EPLAN Smart Mounting: Control cabinet manufacturing just got smarter!

Premiere at the SPS 2022

Time pressures, a skilled worker shortage and communication breakdowns characterise everyday work in control cabinet manufacturing. Solutions provider EPLAN can help mitigate these factors: the new EPLAN Smart Mounting software supports manual control cabinet assembly in a highly efficient manner. It leads technicians step by step through the installation of DIN rails, cable ducts and electrotechnical components, and shows where which component must be installed. Supported by a 3D visualisation, even less experienced technicians can recognise exactly where components must be placed. Combined with EPLAN Smart Wiring, cabling can also be precisely displayed.

Monheim, Germany, 8 November 2022: Control cabinet and switchgear manufacturing is under increasing time pressures and the lack of skilled employees may also be causing bottlenecks in many cases. This is where EPLAN Smart Mounting comes in: the new software – being presented for the first time at the 2022 SPS – leads the way through the entire control cabinet assembly process. It supports technicians in assembling and mounting all the components in a control cabinet and on mounting panels. Presented in a user-friendly way and supported by a 3D visualisation, the technician immediately recognises where components must be placed. EPLAN Smart Mounting provides production employees a complete list of all the work steps to be carried out. It starts with the mounting of DIN rails and cable ducts – as examples – and ends with electrotechnical components including auxiliary switches and timing relays. The browser-based application with a central web server doesn’t require any installation and can be used directly in the workshop, for instance on a tablet computer.

Easy assembly with the right results

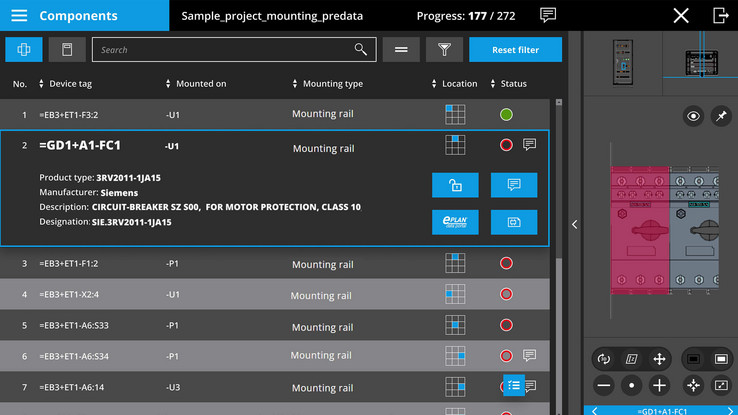

The digital twin in EPLAN Pro Panel provides the relevant engineering information – including dimensions, positioning, drill holes and the type of fastening needed for each component. Technicians can enter comments about components directly into EPLAN Smart Mounting and send them back to the engineering department. This means that the electrotechnical documentation is always up to date – improving communication across departments.

Another practical advantage is that changes to the project can now be quickly implemented. For instance, if there have been changes to the customer specifications to add an additional motor circuit breaker or contactor, the production order can be synchronised – i.e., updated – to the new project. The software shows precisely where components must be removed or which need to be added. This means tedious manual document comparisons no longer need to be done, saving time, and ensuring correct results. And if questions should still arise, EPLAN Smart Mounting provides direct access to the interactive schematics.

Better overview and more flexibility for production managers

It isn’t only workers on the shop floor who gain full support. Production managers also get a better overview and more flexibility – they can see the status of open production orders at a glance. A control system displays the assembly progress for each component: green means completed, while red means not yet processed. If there are resource bottlenecks or downtimes, an order that has already been started can easily be handed off to another employee. In addition, personnel resources can be utilised more flexibly for different production steps.

Great interaction between assembly and cabling

This isn’t yet the end of the process. The data foundation from EPLAN Pro Panel can also be used for cabling. Using EPLAN Smart Wiring means the complete downstream wiring process for the control cabinet can also be system-based. A uniform interface for EPLAN Smart Mounting and EPLAN Smart Wiring, as well as the digital twin from EPLAN Pro Panel as the single source of truth, ensure maximum end-to-end data consistency. The software is naturally compatible with common fully automatic wire assembly machine such as the Rittal Wire Terminal WT. Prefabricated wires can also be used. The aim is to achieve the highest degree of automation possible from the initial engineering phase to manufacturing while at the same time ensuring maximum quality.