Electrical Engineering: Simplifying Variant Designs

New tools and functions for control cabinet manufacturing

The design engineers at Konstruktionsbüro Becker (KBB) in Augsburg, Germany, develop and build complex panels and control cabinets for demanding clients in the specialised machinery construction industry. In recent months, the company has expanded the EPLAN Platform, which they’ve been using for a long time, by adding more tools and functions. They’ve now also simplified the designing of variants using EPLAN eBUILD.

One of the advantages of engineering platforms is that they don’t always have to be used in the same unvarying way. Instead, users can work with them to make step-by-step progress, such as in the direction of automated engineering. This is also true of the EPLAN Platform to a large extent, as shown by the example of the engineering design offices of Konstruktionsbüro Becker (KBB) in Augsburg. The family-run company – with Markus Becker in the first generation and Florian Becker in the second – has been focusing on sophisticated electrical engineering and control cabinet projects for almost 25 years.

Florian Becker (right) and Tim Flinspach have implemented several new EPLAN Platform functions and tools.

Image source: KBB

Classic Specialised Machinery Construction

One of their clients is a manufacturer of lift platforms for the maintenance of trains and trams. Florian Becker: “In these systems, the electrical and control technologies are designed to be decentralised, meaning they’re divided amongst several terminal boxes.” Other customers manufacture exhaust extraction systems, servo-presses, mixing and grinding systems, and winch drives for stage construction. Almost all of them are traditional special machine builders. The often-complex electrical technology is designed on a one-off basis and commissioned on-site. This is where the EPLAN Platform comes in.

On the Lookout for Improvements

Amongst design offices and control cabinet manufacturers, one of the ways KBB holds its own against the competition is by processing orders quickly and on schedule – and thanks to their systematic use of innovations. Florian Becker: “Because we’re passionate engineers, we enjoy testing, inspecting and trying things out. For instance, when EPLAN makes beta versions with new functionalities available, we like to give them a try – particularly to see if the new features make our work easier.”

Simplified Variant Design with eBUILD

KBB has tapped into the trendsetting and future-oriented development of the EPLAN Platform with its cloud functionality. The primary goal in this was to simplify variant designs. As Becker notes: “We’ve been using EPLAN eBUILD to design variants and repetitive components for about six months now.”

The reason KBB values the simplification of these tasks so highly can best be explained using the example of a specific project. For a maintenance lift for trains, nearly 200 substations and sub-distributors (terminal boxes) had to be designed. The terminal boxes are all similar, but almost never the same. Becker: “Using eBUILD we can very easily define a basic configuration that we then adapt to the specific requirements, for instance to the power of the drives or the position of the switchboxes within the distribution network.” While this is more of a coincidental advantage, the KBB electrical design engineers find it to be a crucial one: “For variant design, eBUILD provides very practical software tools that make this an extremely easy task.”

Along with making work easier, EPLAN has a great payment model, as far as KBB is concerned. “We pay annually for a licence token that isn’t related to the specific hardware it’s running on or who’s using it, which is fair.”

eVIEW as a Feedback Channel

Another new feature for the KBB engineers is the viewing function in EPLAN eVIEW. Becker: “We mainly use this function as an internal feedback channel. For instance, employees can insert comments and notes, provide approvals and also include external colleagues. This ensures a workflow that is as simple as it is structured.” It has also proved practical when used on site during installation and commissioning: “Because eVIEW also works on a tablet computer, the installation technicians at the construction site can use their pens to add notes and annotations to the documentation, improving the flow of information.” Another advantage is that this tool is free of charge.

Rapid Implementation of the New Modules and Functions

Since the KBB design team is always busy, it was a good thing that Tim Flinspach wrote his bachelor’s thesis on implementing the new EPLAN functions during his dual work-study programme. Since completing his studies, he’s joined the KBB team and is supervising implementation of the project.

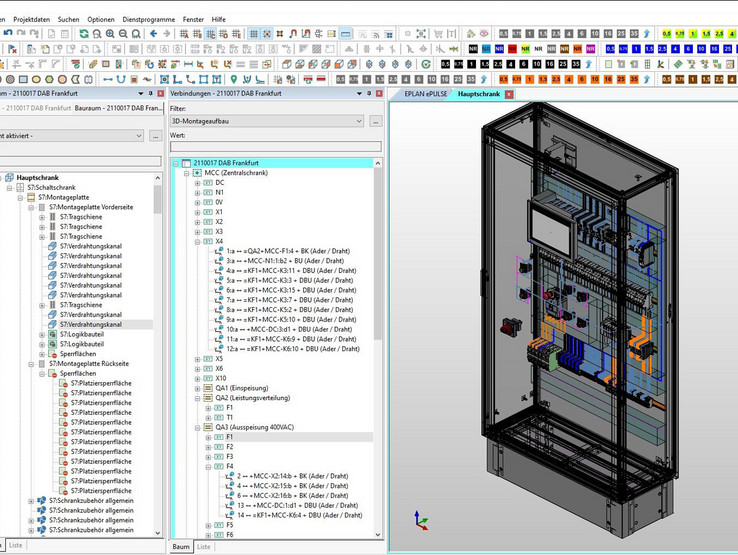

The control cabinet is designed in EPLAN Pro Panel based on the schematics data from EPLAN Electric P8. The 3D model can also be used to derive the automated milling and manufacturing data for the individual cabling assembly.

Image source: KBB

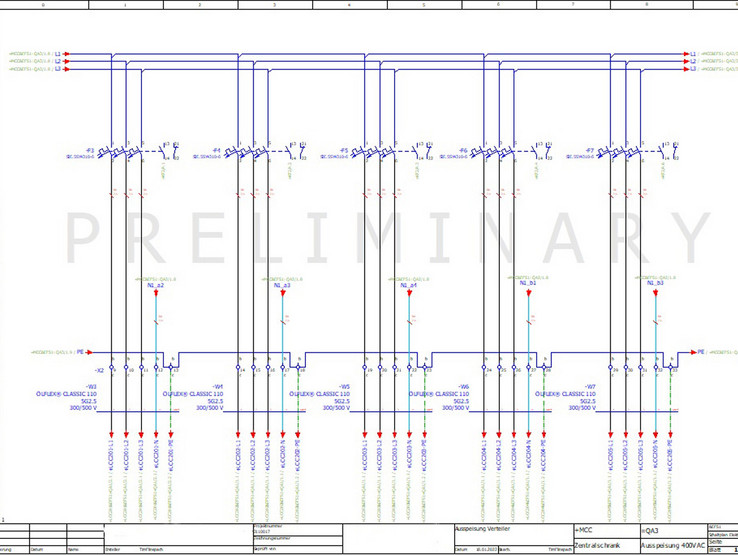

Using EPLAN eBUILD for designing variants and repetitive components also accelerates the creation of schematics in EPLAN Electric P8.

Image source: KBB

Automating the Production of Switchboxes

One part of the project involves switchbox construction. Becker: “We manufacture a lot of smaller terminal boxes and sub-distributors made of synthetic materials. We’ve now automated this step by purchasing a milling machine and generating the milling data in EPLAN Pro Panel.” This works excellently in practice and actually makes production work easier: “We no longer have to saw the cut-outs for displays and control elements by hand, saving time and resulting in a better-looking housing as well.”

Do-It-Yourself Single-Wire Labelling

In addition to the milling system, KBB also bought a system for assembling and labelling individual wires. In the design offices, Arthur Kinder is busy optimising the system’s operation: “We’re still working on colour selection to create ideal readability. Right now we’re exporting the wire lists from EPLAN with all the relevant information including length, cross-section and labelling as an Excel file. Soon, however, the system will be using data directly from EPLAN Pro Panel.”

The new individual wire assembly and labelling system pulls its data from EPLAN Pro Panel.

Image source: KBB

Arthur Kinder optimising the timesaving in-house assembly process.

Image source: KBB

Wiring Without Schematics

Another current optimisation project concerns the wiring and cabling of the control cabinets and terminal boxes. EPLAN is now being consistently used for this, which means that employees in production can also complete wiring and cabling projects without any schematics – and that the wire lengths are always correct without major extra safeguards. Becker: “There’s really a high amount of cabling, especially for the work lifts for rail vehicles, which can be up to 400 metres long. We used to work with cable drums on-site, but now we deliver cut-to-length, assembled and labelled cabling. This saves time and helps avoid mistakes.”

Consulting and More

What was rather unusual for Becker was to take advantage of EPLAN’s consulting support for the described projects: “We usually work on acquiring the necessary knowledge ourselves, with assistance from videos and forum discussions. But the consulting was really helpful here and I highly recommend it. It led to a deeper understanding for us and to a few ‘aha!’ moments.”

The company has planned additional projects for the coming months: “We’ll continue improving the cabling assembly processes, heading toward smart wiring. And we will also be looking at the augmented reality (AR) feature in eVIEW. It offers a lot of potential to simplify service, especially for systems outside of Germany, because we can get an overview of the situation using AR, at least as a first step.”

Author: Gerald Scheffels, freelance specialist journalist, Wuppertal, Germany