Kreutzpointner opts for EPLAN Preplanning

Building Automation: Great Preplanning, Great Standardisation

At the beginning, there are the automation schematics: from this foundation the Kreutzpointner Group plans and designs very comprehensive and complex building technology projects. Thus the decision for the most suitable CAx tool for preplanning wasn’t taken lightly. After two years of evaluations and testing, the company has now introduced EPLAN Preplanning – and hasn’t regretted its decision for a second.

For the managers at Kreutzpointner, the concept and automation are at the forefront of their planning processes. As the Head of I&C/Building Automation Alois Achleitner explains: “This is the only way to achieve optimal results and to best exploit the potential that automation offers with regard to energy efficiency, operating costs, user comfort and flexibility.” What this means at the CAx level is that the structure of the building automation must first be defined before any electrical schematics are drawn. This in turn requires a preplanning tool that also includes the process and I&C technology and whose results can continue to be used optimally in the planning and design of the individual disciplines without any media discontinuities.

Benchmark for systems on the market

Since Kreutzpointner’s electrical designers have been using EPLAN Electric P8 across multiple departments for years now, it made sense to choose EPLAN Preplanning as the most suitable software solution. But the managers responsible for choosing a new tool didn’t make it easy on themselves. Achleitner says, “From our point of view, this decision was of great importance. We wanted to use not just the most convenient, but basically the best system for the job.”

Since there were no time pressures, Johannes Krittl, integration planner and leader of the I&C technology team, identified five leading systems for building automation preplanning: “We first undertook a comprehensive evaluation of these systems according to predefined criteria and then also tested them in practice.” There were particular features that Krittl needed to test: “List exports are an important topic for us. We have to be able to quickly deliver cable lists, data point lists and so on. It’s additionally important to provide very high-quality data very quickly.”

System selection was a challenge

The entire evaluation process lasted almost two years and the results weren’t entirely clear at first. Krittl continues: “We had taken a very close look at EPLAN because we already work with P8 and it best fulfilled the requirement of end-to-end data continuity. But we have really stringent requirements because we’ve been increasingly active in the field of building automation since 2015.” When Kreutzpointner started their benchmarking process, EPLAN Preplanning still lacked several functions that were relevant for the company. “We spoke to them about that and EPLAN made a clear commitment to address those issues in development,” he says. “After another year, seven of the ten issues we raised had been addressed and two more were in the pipeline. On this basis it was easy to decide in favour of EPLAN.”

Preplanning requires prep work

For implementing EPLAN Preplanning, the Kreutzpointner team worked intensively with EPLAN consultants. Krittl: “Because EPLAN came more from the field of industrial automation than building automation, there weren’t yet any macros or templates we could use. We invested more time in this and it paid off, particularly since EPLAN really supported us well. EPLAN will also soon have templates and sample projects based on Guideline 3814 from the Association of German Engineers [German: VDI], which are well prepared. This will make it easier for users to get started and change over to using [EPLAN Preplanning].”

First use in a challenging project

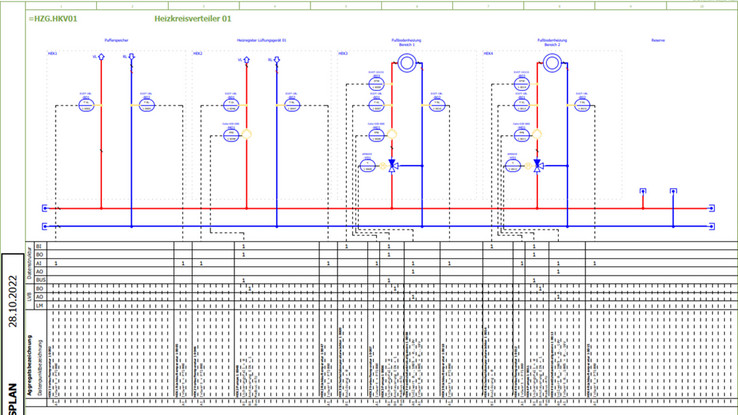

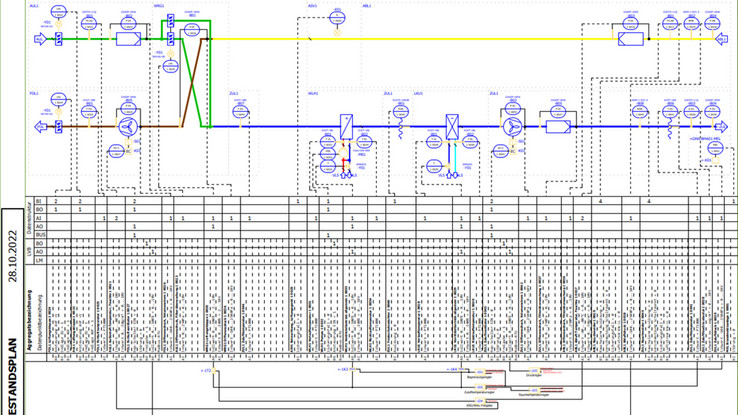

The first project Kreutzpointner started with EPLAN Preplanning was quite challenging. Achleitner explains: “This was and is about I&C technology at its best: an electronics production facility with numerous additional tasks and disciplines including refrigeration technology, clean room technology, positive pressure controls and specific demands for humidity and temperature in many production areas. The hardware alone includes five large and central ventilation units, three chillers and two re-coolers in the outside area as well as a connection to a district heating system.”

Working with the client, the Kreutzpointner engineers first defined a customer-specific EPLAN standard for planning the switchgear systems – while starting with the preplanning in parallel. Krittl: “The client has very comprehensive electrotechnical expertise, which made cooperation much easier and we quickly achieved good results.” The control cabinets – sourced from the Rittal system platform and built in Kreutzpointner’s in-house production facility – have already been installed and teams are currently laying the I&C cabling.

End-to-end digitalisation – from the very start

Alois Achleitner summarises the lessons learned after their first project using EPLAN Preplanning: “The one-off outlays before the start are high. But after that, EPLAN Preplanning delivers what it promises. We can very easily copy the structures and patterns we created and a lot has been clearly thought through, for instance changes later in the process. If for example the client wants to equip fire dampers with one checkback signal instead of two, this can be changed with three mouse clicks – for all dampers. The export options are also very versatile, for instance the data point list according to VDI 3814, which is generated fully automatically. In short, EPLAN Preplanning depicts everything we need for building automation systems, and we can seamlessly transfer the data to EPLAN Electric P8 for partially automated schematic generation. This has brought us much closer to our goal of standardising and digitalising every overall project as much as possible with as few interfaces as possible.”

Next project: automation in control cabinet construction

Kreutzpointner has also already started on another EPLAN project – this time in the other direction, so to speak, towards production. Krittl: “Our employees in the switchgear construction division are introducing EPLAN Pro Panel right now and will then also use the direct link from the design department to the Perforex machining centre from Rittal.” Not only Kreutzpointner itself but also its customers will then benefit from the reduction in the workload since the switchgear construction division works for both in-house and external clients. “This makes us more competitive.”

Author: Rolf Schulte, EPLAN Global Vertical Market Manager Building Technology

Kreutzpointner: An Overview

Expanding the portfolio with building automation: this step was taken early on by the Kreutzpointner Group, headquartered in Burghausen, Germany.

The Kreutzpointner Group is one of Germany’s largest medium-sized enterprises specialised in electrotechnology, switchgear system construction, engineering, IT and solar. Kreutzpointner has been a family-run business since its founding in 1923.

The group consists of seven companies with around 1,200 employees in Germany, Austria and Romania. Kreutzpointner is also responsible for very complex projects in building technology with a high degree of planning expertise and a large vertical range of manufacturing. Projects include the Munich Airport and large hospitals including all disciplines.

The Group works primarily for companies in the chemical, manufacturing, data centre, machine building, medical care and pharmaceutical industries. It also works for public authorities and generated sales of around 110 million euros in 2021. The Group is systematically advancing its building automation projects and expertise.