Best coffee through fluid engineering

Opem has specialised in the planning and design of capsule machines

When production is not standard, but rather customised specifically to individual requirements while also being high-performance, then it is completely necessary for the design instruments to be reliable, as these make the entire product development process more efficient and can optimise the procedure. By using the EPLAN Platform, this objective was achieved by Opem, a company specialising in automatic packaging machinery solutions.

Milky, concentrated, sweet, bitter, pure or with a shot of alcohol. There are many variations and just as many flavours and qualities, in which a good coffee, known to be one of the most widely consumed drinks in the world, can be enjoyed. In a can, in a glass, in a sachet, pads or capsules – coffee has a long tradition, but there are ongoing innovations in the taste and forms of consumption as well. And it is precisely in the world of coffee, thanks to a work group, consisting of about 100 qualified and motivated people under the management of founder and president Fabio Binacchi, that the Parma-based company Opem has been able to take on a main role, both in Italy but especially overseas (where approx. 90 % of the production goes) with a turnover of € 40 million. In fact, the company, founded in 1974, specialised from the very beginning in the design of systems for weighing and packaging pasta, switching to coffee at the end of the 1980s. “The first packaging systems for this product date back to 1982,” says Franco Lupi, the head of Opem’s technical department. “But the real turnaround came in the next decade, when coffee pads became established on the American market.” A real revolution in the consumption of the drink, and one in which the Parma-based company recognised the potential. Soon, it had manufactured a high-speed system for filling the coffee pads for a significant, multi-national American company. Today, decades later, Opem can plan and manufacture systems with a high added value on the basis of the technical development and acquired knowledge, and thanks to the use of efficient software for hydraulic, pneumatic and electrical engineering. In this context, the use of EPLAN Fluid and EPLAN Electric P8 offer the technical department (which is no fewer than twenty people) a solid digital platform, which is based on a shared database, allows flexibility and can react specifically to the operating requirements.

Streamlined and efficient planning of the exceptional

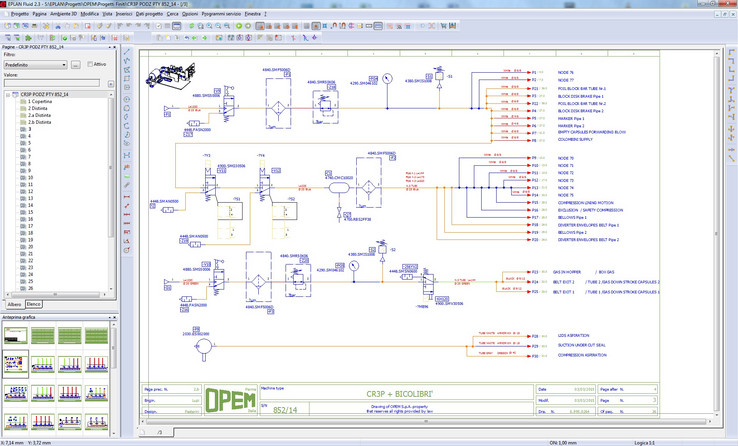

“Efficiency and a high degree of adjustment to individual requirements,” continues Lupi, “are the keywords, which stand for the machinery we develop more than ever today.” “Characteristics, which apply to appliances that are used daily, from which we expect functionality and simple design so that all the intended procedures can be carried out as quickly and accurately as possible. This applies both for the field of fluid power and the field of electrics.” For fluid power engineering, EPLAN Fluid has been used for years at Opem as the specific design instrument for design and automated documentation of circuits of technical fluid power systems in accordance with current standards, such as ISO 1219. Using this digital platform, the technical fluid power design phase is connected with all the other disciplines and activities connected with product development, so that various planning processes are carried out in parallel, optimising time and resources and minimising critical points. “In our case, these critical points,” continues Lupi, “are closely connected with the adjustment of the system to individual requirements. The market demands flexibility from us as well as the manufacture of highly-efficient solutions. In other words: In a short space of time, effective solutions and fundamental changes to the initial model with continual improvements are required by the customer, even after delivery and installation.” EPLAN Fluid was designed and developed to offer a number of advantages in this context, with these being: The acceleration of fluid planning; optimisation of product quality; automated end-to-end documentation; noticeable cost reduction. “In other words,” emphasises Lupi, “we must be able to execute our projects in a completely streamlined manner, from beginning to end, by managing procedural records on several levels about any executed improvements and/or changes.” Against this background, the manufacture of machines to fill capsules (current core business of the company) comprises lines, which can process between 70 and 1,500 to 2,000 parts per minute. A broad span, which indicates the complexity and different technical requirements of all aspects.

Keeping up with the development

The technical department of Opem, which has used EPLAN software to plan the electrics for many years, has used EPLAN Fluid for approx. two years and can fulfil the requirement of faster execution of all project phases and comply fully with the legal requirements. “Before,” explains Lupi, “we created pneumatic diagrams, which were absolutely simple, clear and comprehensible on the one hand; but on the other hand, comprised a complicated task, which increased further with the complexity of the systems, affecting the resources of the technical department. And so, the decision was made to use an effective instrument, which can completely fulfil the operational requirements and correspond to the standardised, operational methods, which can be integrated through other software systems and can be connected with this using interfaces. EPLAN Fluid had these special features for the optimal management of our pneumatic plans and, at the same time, completely complied with international regulations (as already mentioned, approx. 90% of production is exported, author’s note).” Thanks to software with exclusive, logical functions and automatic processes, which were developed to accelerate planning times, these requirements are fulfilled. The user interface with extensive draw functions simplifies the initial phases, while the automatic connections create all fluid connections in a fully-automated manner – with the option of allocating logical properties and carrying out an evaluation in this context. But the important aspect that these are international projects is not neglected here; this is supported through translation into foreign languages. The dictionary available in EPLAN Fluid contains the special terminology of the ISO standards 5598 and can be individually expanded. This software can also determine the rules for planning. The system guarantees that the product is focused on the valid ISO 1219 regulation. The basis is formed by suitable symbol libraries, but the article codes and individual functional elements of the device can be allocated automatically as per the regulation. If the standard changes, the referenced symbols allow an efficient and immediate conversion.

Synergy from functionality and digital organisation

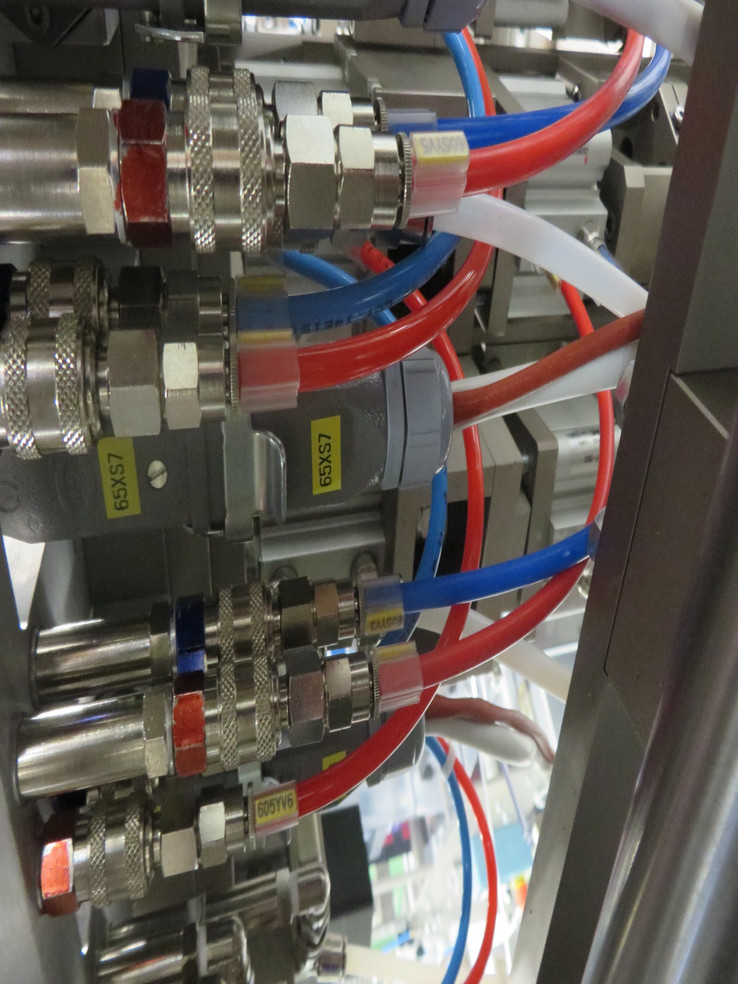

“By using the EPLAN platform for the fluid power section of our machinery,” highlights Lupi, “we were able to optimise the entire planning process and free up internal resources, with the option of having an organised version history, which can be viewed at any time and, above all, can be accessed specifically and exclusively without any loss of time.” Having all components in view, including the small parts, such as connectors, hoses and pipes, creates interesting, operational advantages. The intelligent smart connecting function should be highlighted among the additional functions: If the devices are connected, their connection continues to exist even if the individual symbols are displaced. This improves security considerably, especially if a number of connections are in use. The schematic of the fluid cycle, the material list and 3D diagram are connected directly with each other. The alignment of the components for the 3D assembly plan is then simplified through eTouch technology, as every component has holders, attachment points or specified installation areas. “Better controls, flexibility and simultaneous security of being able to control the entire project efficiently and effectively, irrespective of its complexity. This manifests undoubtedly in a faster commissioning and an added value for the end consumer, as you must not forget that the life cycle of each machine or system that we produce, begins with the creation of the initial material lists and ends when the customer decides to take it out of operation. Until this point, our staff must be able to intervene very quickly, safely and reliably due to changes, complements, etc. Thanks to EPLAN Fluid and EPLAN Electric P8 for the electrical sector, we can fulfil this requirement perfectly,” says Lupi. Secure and reliable and permanent records. And with clear, recognisable data, irrespective of the technician that planned the system. “An organised system standard for us and our customers, which is still very flexible, with the option of expanding a database while having it available directly in any language or regulation you choose. These are the summarised strengths of the EPLAN platform, which continue to increase our competitive ability in the field of continual innovation,” is Lupi’s summary. Author: Gianandrea Mazzola

More and more innovation

Since 1986, Opem has specialised in the planning and design of capsule machines, which are customised to individual requirements. And since then, the company has offered more and more new models. Due to the strong growth of systems with portioning, particularly for coffee, the company began to design ever-faster and more reliable systems to produce capsules for coffee, soluble drinks, tea, etc., which fulfil the expectations of an ever-increasing number of customers. An ever-growing range of systems for small, medium and large production facilities. These are finished and functional machines for use in the coffee production chain, among other things. Above all, the solution of multi-functional systems to process dry and wet mixtures in biodegradable capsules represents the innovation and added value of Opem always being able to offer the market something new due to its flexibility, passion and competence.

Data portal serving productivity

The EPLAN Data Portal, which is integrated into the EPLAN Platform, is a global web service, which was developed to offer online access to useful instrument data. The data can be used in the design stage, whereby the configuration effort is reduced and the quality of the plant or system documentation increases. In the Data Portal, which is continually expanded and implemented by the manufacturer through new solutions and data, macros of partial cycles, filters for intelligent material selection, international descriptions and previews and technical handbooks are available.