ECAD under special conditions

Thee electrical designers have been able to make their work considerably easier by using automation – with EPLAN Electric P8, EEC One and the additional EPLAN FieldSys module.

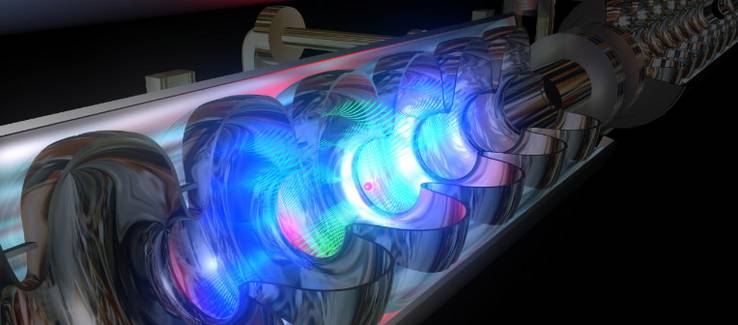

There are lots of extraordinary features in the electrotechnical equipment of the European XFEL in Hamburg: both the components in use and the experimental stations of the unique research facility, which will offer insights into nanostructures, molecules and viruses, among other things, from 2017. Nevertheless, the electrical designers have been able to make their work considerably easier by using automation – with EPLAN Electric P8, EEC One and the additional EPLAN FieldSys module. In the shape of the “European XFEL” in Hamburg, a large facility of fundamental research is being created which will provide new findings for countless disciplines. In a particle accelerator with a length of about 2 kilometres, electrons are accelerated virtually to the speed of light and charged with high energy. Then they fly through a special sequence of magnets (“undulator”) in a slalom course, emitting laser-like x-rays. Scientists and research facilities from many nations are working together to construct the x-ray laser. The major project is being financed by eleven involved states.

X-ray flash produces new findings

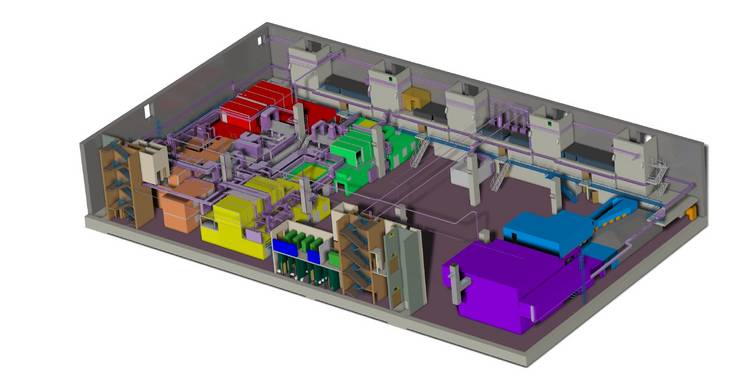

The extremely high-energy x-ray flashes enable new insights into nanostructures and even into individual molecules. For example, they can help to decode the three-dimensional structure of biomolecules. Or they make it possible to film chemical reactions which happen in less than 0.1 billionths of a second. In addition, they enable the observation of cell components and whole viruses. Countless disciplines benefit from the insights produced here. For this reason, six experimental stations will be created in the underground experiment hall, in which world-leading scientists from the fields of biology, chemistry, medicine and particle physics among others will be able to carry out their experiments. The six sections are each equipped with other measuring tools and appliances.

Major challenge for electrotechnical planning

The construction of this plant, which began in 2009, will be completed in 2017. The project is a major challenge for the designers and suppliers involved because new ground must be broken repeatedly in terms of components. For the same reason, the electrical design is particularly demanding. And there are even more challenges. Dr. Antonios-Vassilios Lalechos, who is responsible for the electrical design in the experiment hall at European XFEL, among other duties, (Fig.) says, “The project is extraordinarily complex. There are several thousand valves, which are being connected to the electricity. Therefore, we are placing very high demands both on the design and the documentation. And we are hardly using any “off-the-shelf” components: Most components are being developed especially for European XFEL and if we do use standard components, we often end up using them for purposes other than their original.” Lalechos is also creating the electrical documentation. “The documentation is of central importance because the entire plant is being constantly further developed and modified during operation. For this reason, the engineers always need the latest documentation.”

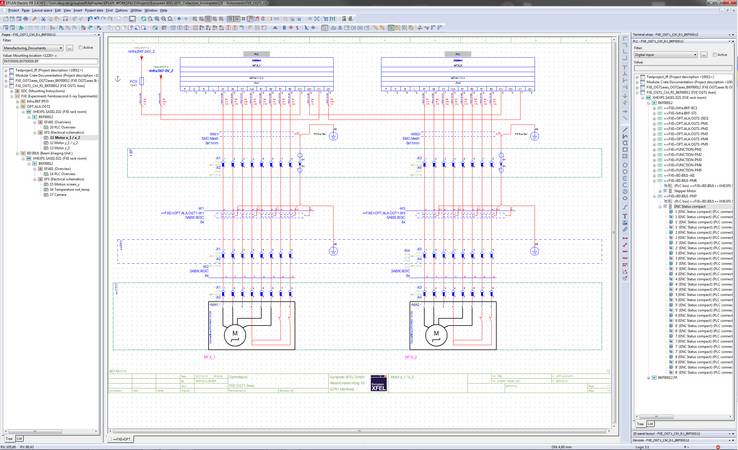

Automated schematic creation – practical even for special projects

Antonios Lalechos is supported in his work by three employees. A concept was initially developed for the demanding electrical design two and a half years ago. This included the decision to use EPLAN Electric P8 and EEC One. This software allows the automated creation of schematics based on an Excel user interface. The design engineer then selects the components or individually defined macros from an individual configurable list, which he can process or vary. On the basis of this, he receives the circuit diagram generated by the system. That the European XFEL designers are using the options of automated schematic creation may seem surprising in the first instance, as the x-ray laser is not a series product and is the only one of its kind in the world. Nevertheless, the automation accelerates the electrical design phase considerably. Antonios Lalechos says, “We have developed macros for various functions, which we vary in each case. We then only have to generate the variations or the deviating planning data.” An example: In EEC One, there is a functional “Detector” macro as a standard design, which is subdivided into various subfunctions and requires several hundred cables in each case: “In total, we generated 165 variations of this macro – an enormous saving in time.” The electrical designers also act in a similar manner when activating electrical motors – of which there are more than a thousand in each individual experimental station, lots in individual specifications – and also when integrating sensors and valves, pumps and vacuum components. Once again, work is made considerably easier by the fact that all the suppliers also develop their products with EPLAN: This creates the prerequisite for a consistent planning tool. Another special feature: The electrotechnical components are not housed in control cabinets. Instead, they are fitted in water-cooled racks. Communication occurs using PCP/ IP, and European XFEL decided on Beckhoff control units.

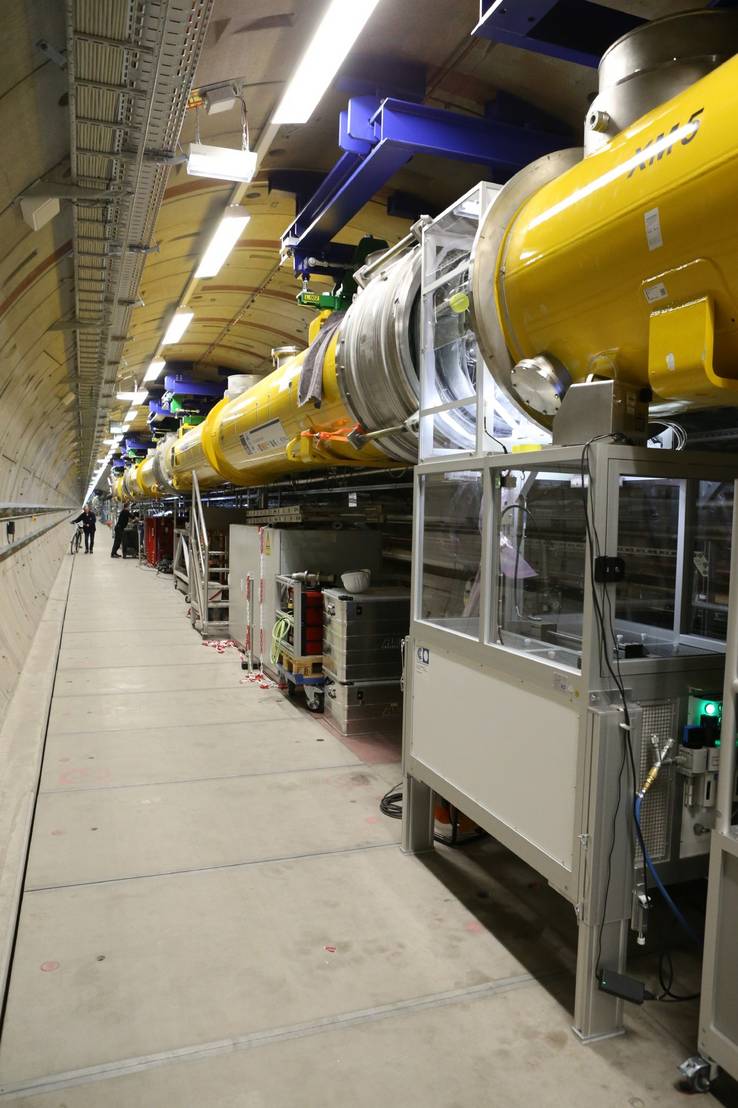

Routing in the tunnel – With time shortages and confined spaces

However, EEC One is not the only automation tool for electrical planning. Lalechos and his team also use the opportunities of automated determination for cable lengths and wiring paths. “Very accurate routing is extremely important for us because the cables are all wired into the tunnel. Both the space and time for installation are equally restricted here. All the more important for us that we have accurate, faultless planning.” This is guaranteed by the EPLAN FieldSys module, which European XFEL uses intensively, “We send the data to an external service provider, who pre-assembles the cables with special connective elements. The installation itself is then very quick and the cables always fit.”

System flexibility is crucial

Why have the electrical planners at European XFEL decided on EPLAN? Antonios Lalechos says, “The macro functionality and routing were crucial to us. The first function accelerates the planning phase and the second speeds up the installation of complex electrical systems in the experiment hall.” The extensive flexibility of EEC One is also very important to the planners, “We are working almost exclusively with “unusual” customer-specific components which we integrate into the electrical planning. We are virtually unable to transfer anything from the EPLAN Data Portal. For this reason, EEC One is more of an integration tool than a development tool for us and it fulfils this task to our complete satisfaction.”