Electrical engineering - digital is faster

EPLAN Platform in action at HPS

Hanseatic Power Solutions (HPS) reckon on just 6–8 weeks to design and construct highly complex switchgears – and they’re often even faster. This is possible only by electrical design being as consistent as possible and highly automated. In addition to EPLAN Electric P8 and EPLAN Pro Panel, HPS are also using the “Copper” module and, just recently, the new EPLAN Cogineer.

Jeddah, Mecca, Benin City. These are some of the locations where personnel from Hanseatic Power Solutions GmbH (HPS) have recently installed switchgear systems. Many systems are also travelling the high seas, i.e. on ships. There are also large HPS systems in locations neighbouring the company base in Norderstedt, Germany – e.g. at the University Medical Center Hamburg-Eppendorf (UKE).

Core expertise in emergency power supplies

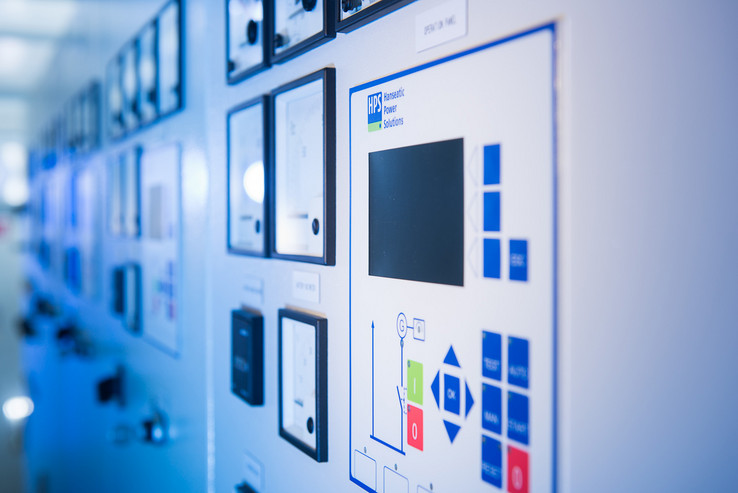

All HPS systems have one thing in common – they all operate major energy generation systems. Michael Grenz, commercial manager: “We mainly focus on switchgear systems in power engineering, especially emergency generators, e.g. in power plants and public buildings. A further area of activity concerns compressor control system on ships.” In-house manufactured products such as controls and operating panels are also being used.

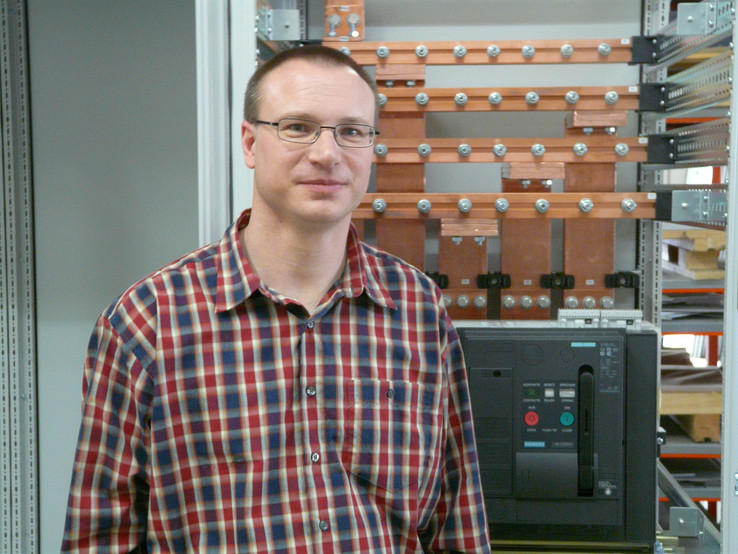

HPS has been exceptionally successful in its specialist area of work. The company was created only in 2009, as a spin-off from a large group of companies, and now employs around 80 staff who include many designers due to each system requiring individual planning and being capable of reaching huge dimensions. Christoph Lange, head of project management: “In our largest project so far, we designed and constructed 140 metre switchgears for the emergency energy supply for a power plant.” The system controls, for example, the pre-heating of oil and coolant for 44 diesel engines.

Quick project completion: 6–8 weeks for design, construction and delivery of the switchgears

The time schedules that HPS sets itself are very tight especially because the projects are large and, without exception, concern one-off systems. Michael Grenz: “From the award of a contract, we reckon on 6–8 weeks for planning, approval, construction and delivery of the switchgear. We often manage it much quicker because time pressures on projects is high.”

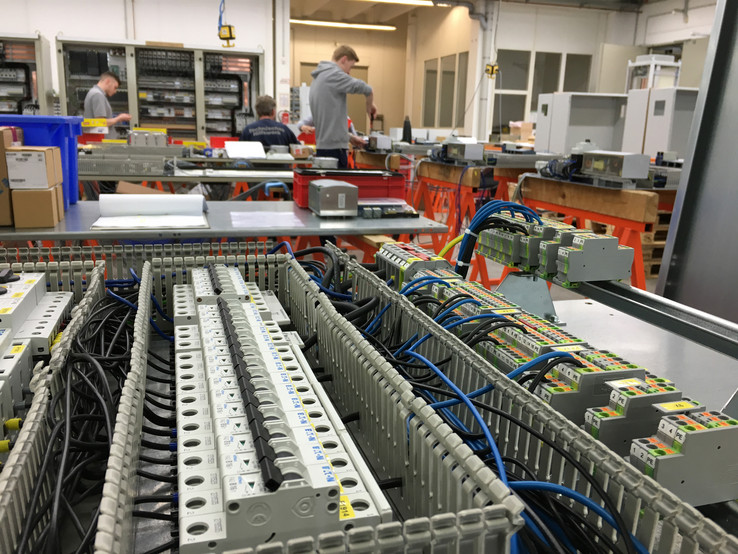

Fast completion of the design phase and perfect processes in the construction of control cabinets are therefore required. This is achieved by HPS using the EPLAN Platform. Electrical engineers work with EPLAN Electric P8, and EPLAN Pro Panel for control cabinet construction. They aim to automate repeatable tasks as far as possible. Christoph Lange gives an example: “We have created macros for the individual functions such as the pre-heating of coolant. This significantly speeds up the design process.”

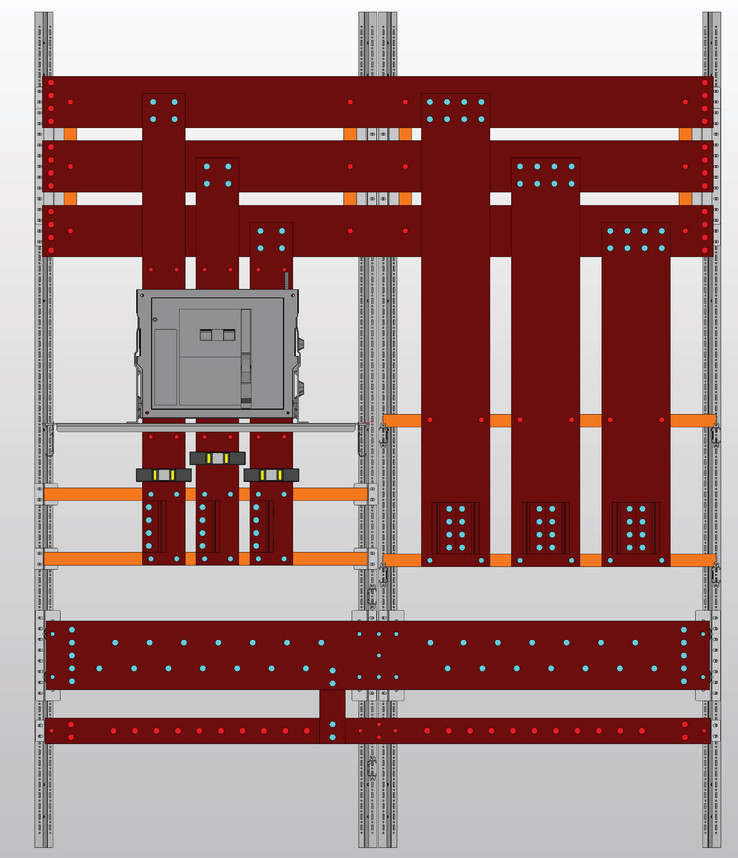

“Copper” extension module for busbars

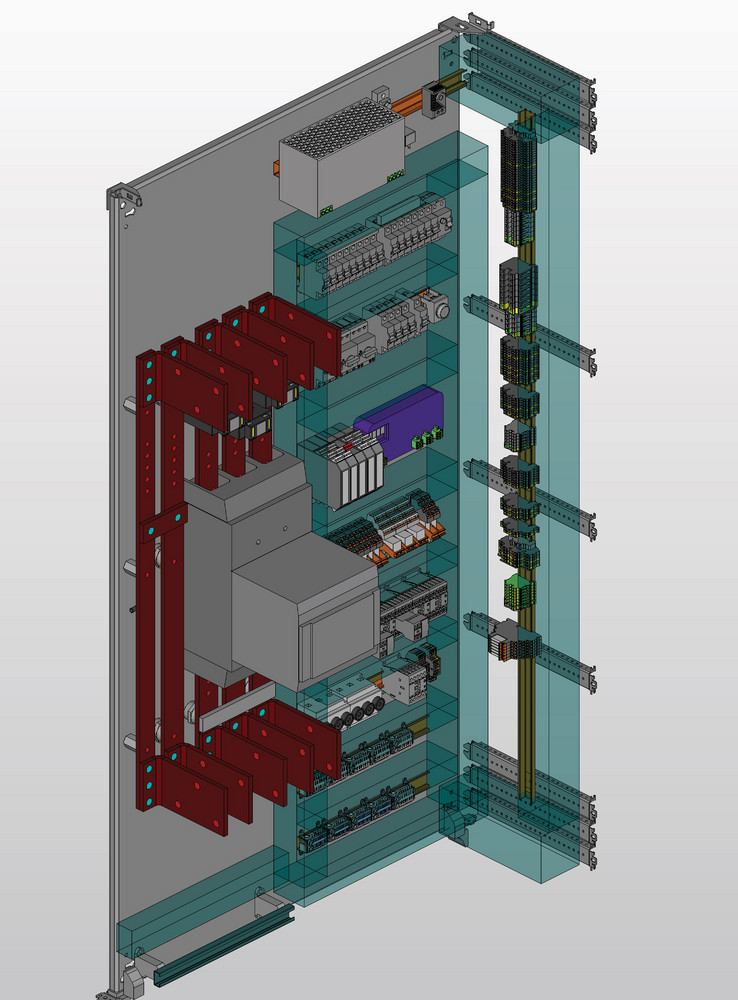

HPS recently extended the EPLAN Platform with the “Copper” extension module from EPLAN Pro Panel to support the design and manufacture of busbars. Christoph Lange: “We design low-voltage switchgears up to 6300 A, energy distributors up to 5000A and medium-voltage switchgears up to 24kV. A lot of copper is therefore built into the control cabinets.”

The module enables the busbars to be mounted virtually in a 3D model of the (also virtual) control cabinet. The designer then simply transfers the results into the overall project. Not only are the outlines of the copper rails defined but drill holes are also automatically positioned. This gives HPS three main benefits. Christoph Lange: “Previously, staff to measure and draw prior to every step. Now they simply work according to the drawings when shortening, bending and drilling. This saves time and the results also look better. Furthermore, the customer can view a 3D image of the control cabinet including copper rails already at the conception phase. Our customers really like this.”

Cable assembly and mechanical production – all automated

While the copper rails are manually processed, manufacturing of the control cabinets is automated throughout. EPLAN Pro Panel is used here. Following approval, data from the 3D control cabinet construction is sent to a sheet metal processing unit which automatically carries out drilling. Cable assembly is carried out similarly. EPLAN Pro Panel is used for the routing. Christoph Lange: “We send data to an external assembly provider. This works perfectly and we are quickly supplied with the required cabling including a high level of detail such as the special labelling of individual wires.”

Links to the ERP system

Once the design has been approved by the customer, the designer sends the complete design, including 3D views and bills of material, to an ERP system. Procurement and prework are then carried out. Michael Grenz: “We order all the necessary components or retrieve them from the stores.” In an ongoing process, production times are recorded precisely so that recalculations can also be made: “In projects subject to quick completion, it is especially important to keep a close eye on time and materials.”

Digital documentation in place of paper folders

Consistent digital design extends beyond manufacturing and installation. Michael Grenz: “Previously, we provided documentation in the required language in up to 20 folders. Every control cabinet today gets a QR code. The user scans the code and downloads documents such as schematics, system descriptions and operating instructions for the components for the relevant cabinet –and the user can be assured that the documentation is always current because we constantly keep it up-to-date.”

HPS recently added the design and construction of medium voltage systems as another field of activity, with the schematics being created with EPLAN Electric P8. Christoph Lange: “We are feeding the system with the necessary data. The designers are intensively using the EPLAN Data Portal.”

Further automation solutions to be implemented soon

Another ongoing project is the implementation of EPLAN Cogineer, the new rule-set based software for automated generation of schematics. A rule set and configuration interface can be created fast and intuitively without requiring any high-level programming knowledge. Only experience in macro technology is required. The aim of developing EPLAN Cogineer was to make schematic design more efficient and faster. And this has obviously been achieved. Christoph Lange: “The system’s test version convinced us. Only the formalities are now required to complete implementation.” HPS again needed to be quick and become one of the first users worldwide to apply this new automation system – it was launched by EPLAN just recently in May.