Intelligent gears, intelligently wired up

With continuously variable automatic transmissions, VDS Getriebe GmbH helps manufacturers of agricultural and municipal utility vehicles to increase their efficiency and life span.

With continuously variable automatic transmissions, VDS Getriebe GmbH helps manufacturers of agricultural and municipal utility vehicles to increase their efficiency and life span. By using patented, modular elements that are developed specific to the model, the transmissions are mechatronic units with drive management which ranges from the motor to the wheel hub. Since summer 2014, electrotechnical components have been developed with EPLAN Electric P8 for schematic creation and with EPLAN Harness proD for wire harnesses. The integrated 3D tool allows the mechanical and electrical development to occur in parallel, leading to a considerable reduction of the time to market. If you have driven a car with a continuously variable transmission before, then you will know the feeling of being able to accelerate non-stop from stationary to the maximum speed without changing gear one single time. Transmitting the motor output consistently from the combustion engine to the wheels at all speeds creates optimal drivability. This requires gears, the transmission ratio of which can be continually adapted.

Never change gear again

Since motor vehicles have been in production, there have been attempts to design gears to be continuously variable. This is more than just an added comfort for the driver. Particularly in fields such as agriculture, in which vehicles operate in extreme situations with threshold friction, the interruption of the power transmission through gear changes can lead to wheel slides. The result can be slipping or getting caught. “The time is ripe for efficient drive systems. Not just for cars and HGVs, in which the search for fuel consumption savings is producing ever more complex systems, but also for building and work machinery,” says Dipl.-Ing. Heinz Aitzetmüller. He is committed to the development of continuously variable automatic transmissions (CVT) and founded VDS Getriebe GmbH in Wolfern near Steyr (Upper Austria) in 2009. “In tractors, continuously variable transmissions with hydrostatic-mechanical power splits have been on the market for years and prove daily that efficiency and continuous variability do not need to be contradictions.” Aitzetmüller knows what he is talking about. After all, he was very involved in the development of such transmissions at his previous employer’s before the foundation of VDS (Variable Drive Systems). “There are no standard products in this field. VDS develops the right transmissions for each specific case,” he says. “This is the only way to create a balancing act between the optimal utilisation of power, maximum fuel efficiency and reasonable manufacturing costs.”

Mechatronic units

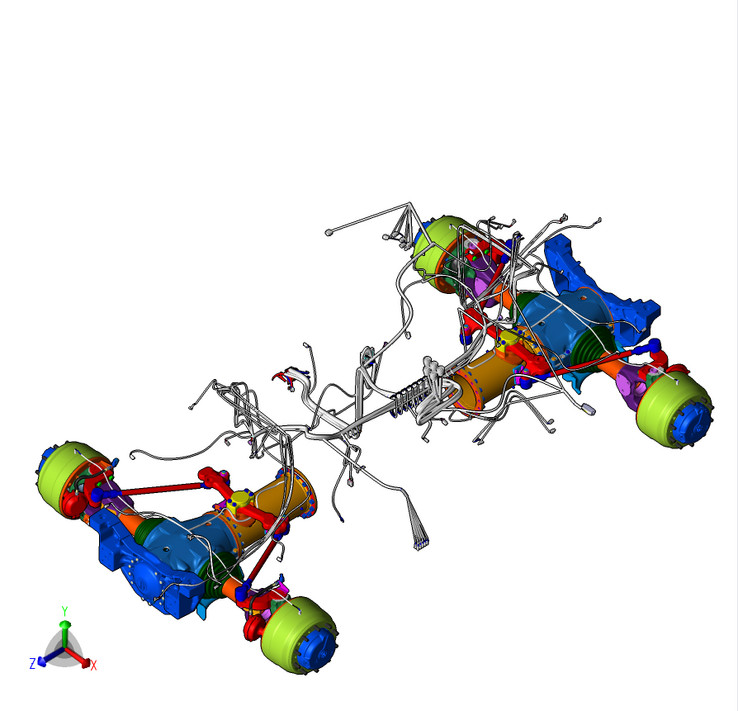

According to Aitzetmüller, the key here is a balanced relationship between the power parts, which in the power-split transmissions are transmitted mechanically or through the hydrostatic or electrical variator. Only the optimal combination of power branches from motor through to wheel hub allows the end consumer to experience the full benefit of the technology. The merger of power branches and the control of the transmission ratio occurs through several planetary transmissions. An electronic drivetrain management system carries out the gear changes and controls the variators. Proportional valves to control the hydrostatic drive and the multi-disc clutches, together with almost 20 sensors that are fitted directly to the rotating components to record the speeds and pressures make the patented VTP and VPD transmissions complex mechatronic units.

Wanted: Mechatronic tool

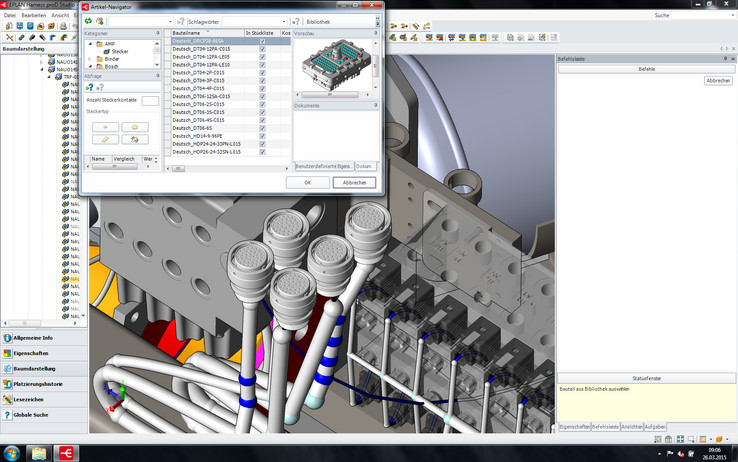

“As long as it was ‘just’ about the wiring of the transmission itself – the control unit is attached externally as an encapsulated unit – and the transition to series production was carried out by the customer, we designed the wire harnesses in a purely mechanical manner,” says DI (FH) Jürgen Fehringer, head of software at VDS. “When a customer asked us to develop the transmission, control unit and, as a result, the wiring for the entire drivetrain of his all-wheel municipal vehicle through to series production, it was clear to us that we had to upgrade our design tools.” “Our aim was to find a mechatronic tool, with which wire harnesses could be developed in 3D based on the schematic and on the mechanical design,” reports design engineer Davidson Pilsner. “From the very beginning, we were convinced that expensive prototypes and/or unsuccessful attempts could only be avoided by working with 3D models, so that the development can be done in the short times required without any loss of quality.” “The choice of suitable software tools was surprisingly large,” remembers Davidson Pilsner. Among others, an appropriate add-on product for the mechanical engineering 3D-CAD system used in-house can be obtained. “However, from its complexity and price, this seems more suited to the construction of wiring for entire aircraft in global teams,” smiles Jürgen Fehringer. “During my Internet research in the spring of 2014, I came across the EPLAN Harness proD, a product which better suits our company size of 22 employees.”

Electrical design from the schematic

With EPLAN Harness proD, the technicians of VDS found an extremely convenient tool for efficient 3D wire harness development, which combines the data from the mechanical and electrical design into one system. An essential deciding factor was the option of starting the electrotechnical part of the product development by creating the schematic by combining EPLAN Electric P8 and then continually accessing standardised electrical engineering data during the rest of the design. Presentations with direct reference to the particular tasks of VDS were convincing and so the decision was made to install EPLAN Electric P8 and EPLAN Harness proD in summer 2014. “After basic training, I compared the product with alternatives again using the knowledge I had acquired,” reports Davidson Pilsner. “The comparison confirmed the accuracy of the decision. In practically all points, EPLAN Harness proD permits considerably more fluid work.”

Consistent data without double entry

The workflow is clearly structured: Initially, the schematic and resulting material lists are compiled in EPLAN Electric P8, normally by Jürgen Fehringer. This data is then transferred via XML interface to Davidson Pilsner, who works mainly with EPLAN Harness proD. In the wire harness software the data is then coupled with the information from the mechanical system. “As this import procedure can be repeated as needed, there is no need for lots of manual data management – especially in the case of subsequent changes to the electrics,” he says happily. “As a result, it is guaranteed that all the data is the same; inconsistencies and errors caused by this can be virtually excluded.” The option of importing data from connectors and other components from the manufacturer’s catalogues also saves a lot of work and eliminates sources of errors. The same applies for the output of lengths, cross-sections and labelling information for the individual cables and wires, which can be produced either as PDFs for the workshop or as data records for EPLAN Electric P8 or for packing machines.

Parallel mechatronic development

After the first project completed without any difficulties within the time targets, no representative statement can be made yet about the direct time saving in designing the wire harness and nail boards. After all, both technicians still had to familiarise themselves with the new software tools and develop routines at the same time as their actual work. The considerable effects of the reuse of previously designed parts is also completely missing from the initial project. “The actual useful effect is the option of completely transforming the development process of our complex mechatronic products,” says Jürgen Fehringer. “Previously, the wire harness could only be manufactured after the mechanical prototype was completed.” Measurements were taken from the prototype for this and the cable routing was defined on this basis. Often enough, mechanical changes were the result because there was no space to feed through the cables, for example. Today, the wire harness can be developed at the same time as the mechanical design and in coordination with this. In this way, lots of tests can be done on the computer screen before the prototypes are constructed. In addition, data can also be transferred from EPLAN Harness proD to the MCAD system, so that the geometry of the wire harness is automatically taken into account in all collision testing. The mechanical and electrical components of the prototype simultaneously reach the test bench – already in their optimised form – where they are “married” with one another and are immediately available for tests. Heinz Aitzetmüller says about the pleasing effect, “Through the parallelisation of mechatronic product development, we can help our customers to considerably reduce their product development time.”

The improvement of the efficiency of agricultural and municipal utility vehicles is the purpose of the VTP and VPD patented continuously variable automatic transmissions from VDS-Getriebe GmbH.

© VDS