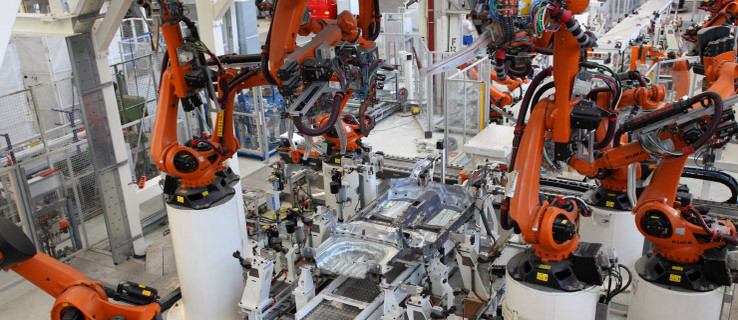

Modular body production lines

Volkswagen innovative: EPLAN Engineering Center “from construction to configuration”. With the objective: increasing quality and 50% time saving in construction.

Pioneering work is important to an automobile manufacturer that claims to build “the car”. And to build precisely these successful cars, each year the Volkswagen marque plans and constructs on average 3 new production plants in various countries, each with hundreds of robots. A growing number of vehicle derivatives and simultaneous reduction in production for each vehicle derivative presents new challenges in the planning of production volumes. It pushes the definition of standards into the foreground, together with the question of how to model these. For this reason, since 2009 the Volkswagen marque has been successfully using modular construction in its planning of plant electrics together with the EPLAN Engineering Center (EEC).The centrepiece of the EEC is a modular system with configurator for the generation of circuit documentation with rule-based plausibility checking. Almost all mechatronic dependencies are taken into consideration in the modular approach. The data originates in a central model (Single Source of Truth). The Wolfsburg company wants to persuade its suppliers of the benefits of this innovative working method – with growing and positive resonance.

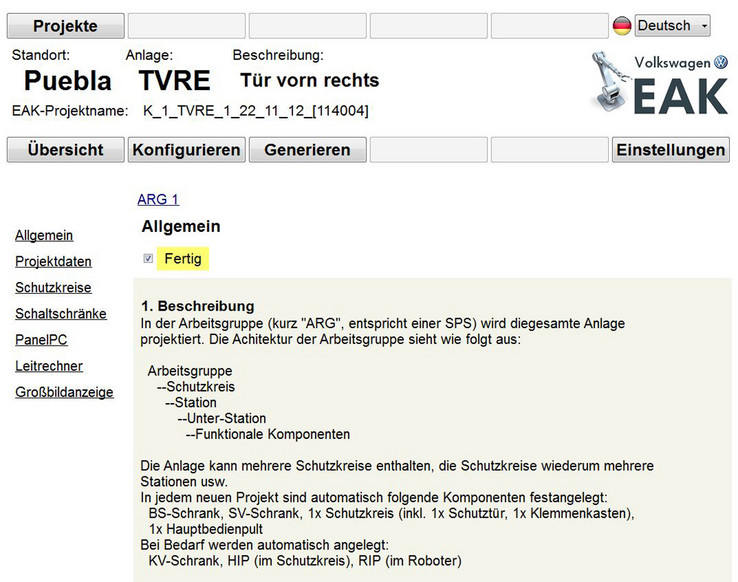

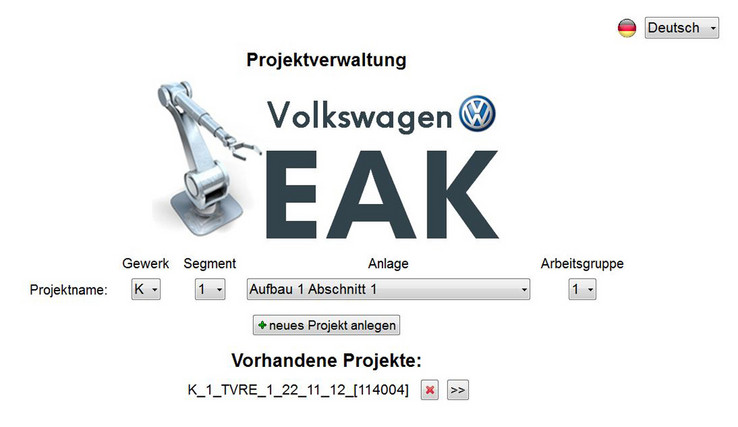

“The configuration solution realised with the EEC is called the Volkswagen Electrical Systems Configurator” (Volkswagen Elektro-Anlagen Konfigurator, VEAK). The team headed by Steffen Strickrodt, electrical systems planning engineer, has developed the individual configuration environment in close collaboration with EPLAN. “With the VEAK, we have created a user-friendly and simple environment in EEC for ourselves and our suppliers that is precisely tuned to our standards”, explains Strickrodt during our interview in one of the brick buildings of the extensive Volkswagen works in Wolfsburg, with a panoramic view over the port facilities and automotive city. Functional engineering: work in parallel rather than in sequence.As an automotive engineer, Steffen Strickrodt likes to compare the principle with the vehicle configurators that almost all automotive manufacturers offer on the Net: In the same way that you can configure your dream car via a number of dialog boxes, the VEAK guides the project engineer through configuration of a body production line in the most user-friendly way possible.

In the conventional sequential process, mechanics planning commences with dimensioning and layout dimensioning; then this data is passed on to electrical planning, which is in turn responsible for automation of the production line.

With the VEAK, this sequential working method is to be run in parallel with the respective underlying interdisciplinary linking information, duplicated input of the same information is to be reduced over time. In order to be able to model this, mechanical components of a body production line are regarded mechatronically. Mechanical components such as industrial robots, turntables or safety doors are modelled in the VEAK with their interdisciplinary linking information – for example, their representation in the circuit diagram.

The VEAK user configures the mechanical model of the production line with the addition of information to model a circuit diagram – among other things, specification of the wiring sequence. The result is predictable due to this procedure, errors caused by “copy & paste constructions” can be avoided and it is possible to guarantee maintenance of standards. Preliminary work that pays offThis requires a certain amount of preliminary work, which the VEAK team has been performing since the end of 2009 in collaboration with the Planning department and EPLAN: the multitude of possible components has been arranged hierarchically into A, B and C elements; A and B components must be available in the configurator and cover about 45% of requirements; C components are “nice to have” – whether they are included in the modular system depends on how often they will be used and how difficult they are to model.

Body production lines are to be fundamentally associated with special machine construction. In this respect, organisation into optimum modules is necessary: The correct size of the modules is decisive so that they can be joined together into a functional overall picture.

Since the project engineer undertakes configuration of the body production line, they must also ultimately bear responsibility for the result. The structure of the VEAK environment allows configuration of individual modules in a targeted yet consistently clear manner via an integrated ‘traffic light’ system. Time saving of up to 50 per centThe preliminary work that the VEAK team provides with the configurator pays off: For example, in this way the basic structure of a work group with an approximately 300-page circuit diagram “can be configured within two hours and has a maturity level of 70 to 80 per cent”, explains Steffen Strickrodt.

The remaining 20-30% must be constructed manually; this takes place using EPLAN Electric P8, as is usual for construction companies at Volkswagen.

Manuals are provided in order to attain a result in the most targeted manner possible in this work step; if the design engineer follows these, they will have a “circuit diagram that is correct after the test run”.

“Suppliers are confirming in a current survey: the VEAK is producing time savings of about 50 per cent”, reports Steffen Strickrodt. The higher quality of the automatically-generated circuit diagrams is paying off already, with respect to checking and double-checking of the circuit documentation. New process model offers considerable advantagesWith the VEAK, guidelines are modelled for the maintenance of design specifications which can in turn reduce the threshold for entry into projects: “Companies reduce their time spent adjusting to the specifications of Volkswagen standards”.

The goal of the VEAK is to reduce complexity for production line design, to increase the market of possible contractors and thus attain considerably more overall flexibility in production line construction. This is consistent with the Group strategy of modularising and standardising production lines (modular production approach). “Whoever knows about the modular approach wants to have it”At present, the VEAK is being used in projects for the plants in Puebla, Bratislava, Emden and Zwickau. Before implementation, the companies are familiarised with operation of the environment and the results in a two-day workshop. “On the first day, we demonstrate what the modular approach can do, how the environment is structured and how the circuit diagrams are produced in EPLAN Electric P8; on the second day, the workshop participants themselves work with the modular approach, and at the end we collect feedback for optimisation of the VEAK”, says Steffen Strickrodt, describing a typical VEAK workshop. The VEAK is to be used by the contractor on each of the Volkswagen marque’s new body production lines, “this helps to maintain our standards” – and to save the users time and expense.

Reference projects such as the new body production line in Puebla, which comprises about 350 robots in approx. 50 work groups, are important for establishment of the VEAK. Each work group thus contains up to 12 robots with a circuit diagram of up to 300 pages. With 50 work groups, this means approximately 15,000 pages of circuit diagrams.

When users are asked about their satisfaction and the potential of the system, they react positively; initial reservations were quickly removed by the VEAK team in the workshop. Users quickly realise for themselves the possibilities and advantages that this innovation offer them. Ambitious visions The VEAK team has set itself ambitious goals: “We would like to become an integral part of electrical systems planning, and in future want to be taken into consideration in the design of all new production lines”.

To achieve this, secure interfaces for communication with suppliers are necessary. This year, the modular approach is to be implemented as a Web-based configurator so that in future releases can be carried out uniformly on a central server, wherein nothing will stand in the way of global availability.

Furthermore, the VEAK will soon be expanded with the discipline of Software so that PLC programs for body production lines can also be automatically generated. Fundamentally, the EEC offers the technology to automatically generate all project-specific documentation such as tenders, bills of material, 3D models, circuit diagrams or software. “We have a revolution in electrical engineering in our hands, and we want to resolutely promote it together with a strong partner such as EPLAN”.

Standardisation and automation of electrical design follows the high degree of automation in production.

Picture: Volkswagen