Fast and Error-Free Project Planning

First preview of the upcoming EPLAN Platform 2024

The curtain is being lifted at the Hannover Messe: get a first glimpse of the upcoming EPLAN Platform 2024, revealing new mathematical calculation functions, greater ease-of-use for terminal management, and unprecedented possibilities for navigating through the 3D model of a control cabinet. It also facilitates creating the digital twin in EPLAN Pro Panel. Another improvement can be found when dealing with machine cabling in conjunction with EPLAN Harness proD, whereby spare cables can be connected in no time at all moving forward, with just a simple click of the mouse.

Hanover/Monheim, Germany, 18 April 2023 – Using automation for fast results is the maxim at many companies these days, something for which the EPLAN Platform offers perfect support. The current Version 2023 already ensures speedy project planning – via cloud-based device management, multi-norm support for schematic macros, and the fast 3D graphics core. At the Hannover Messe, solutions provider EPLAN will be providing an initial preview of the upcoming Version 2024, which is focused on making the software even easier to use.

Calculation functions for block properties

Easily linking objects such as motors and circuit breakers with one another? This is a proven working method on the EPLAN Platform with the “Block Properties” function. The advantage for users is that they can access the properties of multiple objects simultaneously and link them as needed. These block properties are being expanded with a calculation function in the upcoming Version 2024, with basic arithmetic and mathematical functions plus statistical comparison operations.

Aside from now being able to calculate the various object properties in the schematics, these properties can also be compared with one another – directly in the application. For instance, if a user wants to calculate the current based on the motor’s power, the new system support ensures quick results.

The advantages for users are clear: important design decisions based on calculating electrical parameters – for instance selecting the appropriate protective device – can be made directly as the schematics are being created. This saves time and ensures correct results, for instance when cable gauges based on predefined loads must be determined or the total resistance of cables must be calculated based on the gauge and cable length.

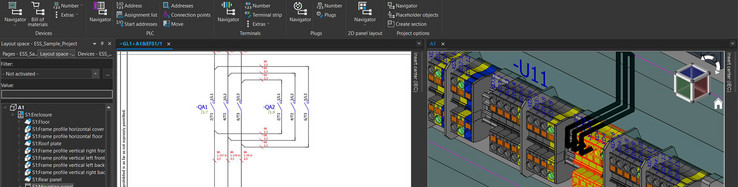

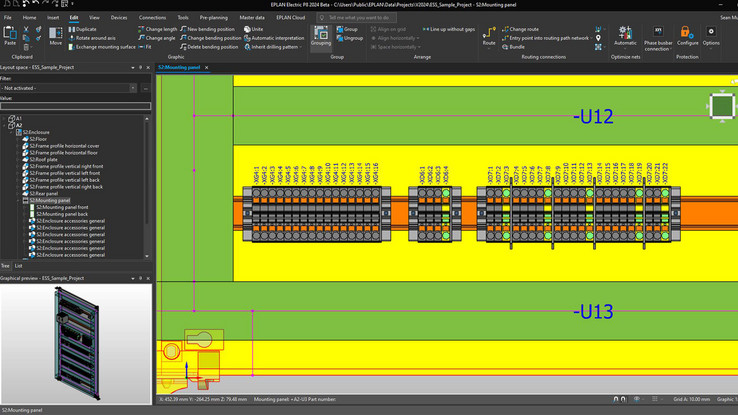

3D navigation for designing control cabinets

Another exciting feature for design engineers is the new 3D Navigation Cube, which simplifies viewing the 3D layout of a control cabinet – also making it much easier to create the digital twin in EPLAN Pro Panel. 3D views and surfaces can easily be selected and conveniently rotated during the design phase using this function. Another key practical advantage: gaps that occur when placing components on DIN rails can, if desired, automatically be removed by the software. Components are therefore placed next to each other in a space-saving and optimised way. This provides more space on the rail, an orderly structure, and more flexibility for placing additional components.

Machine cabling also considered

The current EPLAN Platform 2023 already simplified machine cabling for control cabinets that contain actuators and sensors. The cable editor allows cables to easily be managed and visualised on the EPLAN Platform – regardless of the number of wires. Device and type numbers, source and endpoint, shielding and connection are graphically displayed in a single dialogue panel. The cable editor thus forms the foundation for virtual machine cabling. This is interesting as far as cables and their connection points to the control cabinet can be planned. Traditionally, however, not all cables are assigned. However, the upcoming Version 2024 will now also allow spare cables to be automatically connected. The system also creates spare terminals to achieve this, which can then be automatically connected by the system via the spare cables with just a click. To calculate the voltage drop, the previously mentioned calculation function for block properties comes into play again, ensuring correct results. Additionally, should a length calculation for the cables to reach the machine be required, then EPLAN Harness proD is used, ensuring precise measurements and designs.

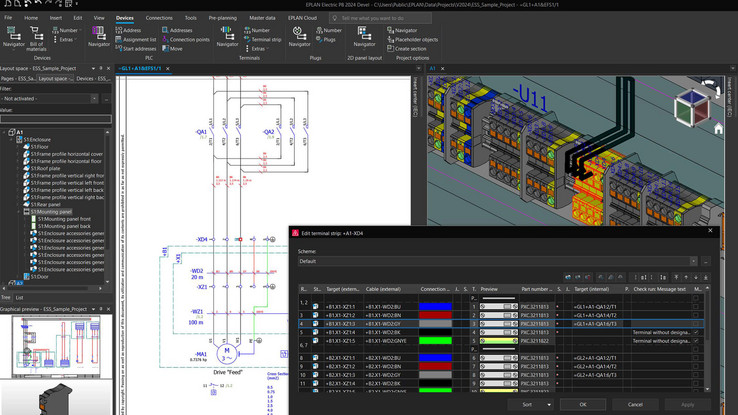

Optimised Terminal Editor

Terminals and terminal strips are traditionally designed using the Terminal Editor in EPLAN. Version 2024 is making managing this even easier. Using the Terminal Editor, users can manage terminal accessories more easily and directly check and validate the terminal strips. This additionally means that terminal connections can be viewed directly in the schematics and individual parts can quickly be selected and/or added to the terminal strip. It’s easy, saves time and convenient – and ensures correct results yet again.