New version 2.7: EPLAN Preplanning with piping module

The earlier you structure and consistently acquire data for engineering, the better. This especially applies to key connection data in early project phases, including piping definitions and information as well as cable data. The new version of EPLAN Preplanning now includes its own piping module. Users also have the chance that cabling data can be defined as specifications for downstream engineering processes. Central management of this connection data reduces the efforts needed while increasing project quality.

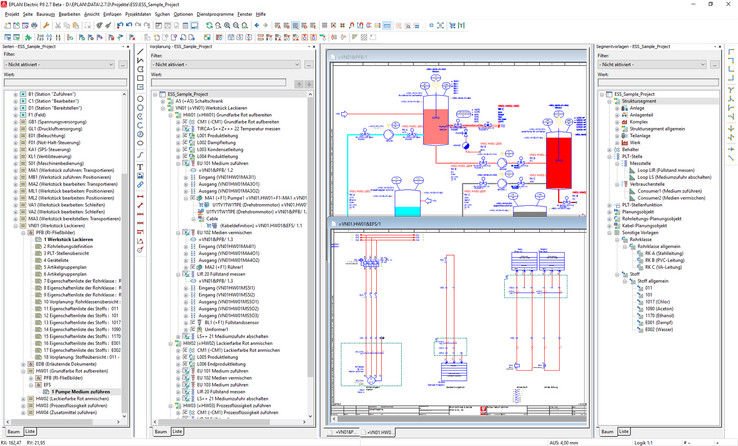

The earlier you structure and consistently acquire data for engineering, the better. This especially applies to key connection data in early project phases, including piping definitions and information as well as cable data. The new version of EPLAN Preplanning now includes its own piping module. Users also have the chance that cabling data can be defined as specifications for downstream engineering processes. Central management of this connection data reduces the efforts needed while increasing project quality. Monheim, Germany, 20 June 2017 – The forthcoming EPLAN Preplanning version 2.7 will be available in September, further expanding the EPLAN Platform’s fields of application. Earlier acquisition and definition of project information and planning – equal parts graphic and database oriented – helps make engineering processes more integrated and efficient, from basic engineering to detail engineering. This is achieved with what are known as connection-planning objects, which define which segments are connected to one another and describe for instance piping or a cable in preplanning. The data that describes the piping includes the pipe class as well as the substance flowing through the respective piping – including water, oil or oxygen as examples. In the Segment Template Navigator, users can define the required pipe classes and substances for a project as templates with all the relevant data. Users no longer have to individually input the data in segments and piping definitions – thereby accelerating projects. The pipe class is a property for all segments in preplanning in the new Version 2.7 and available as an input field for the piping planning object and piping definition points, whereby the selection of a Pipe Class Template is also possible. For the Pipe Class Template, users can additionally store parts such as pipe sections, fittings and pumps. Only those parts assigned to a pipe class can later be selected as components for the segments. Beneficial to users: The piping’s course, meaning the representation of which connections belong to the piping, is automatically determined by EPLAN Preplanning. The pipe class and additional data can be stored via the corresponding characteristics for connections, connection definition points and functions. The selected piping can be colour coded using the pipe routing, and adding additional auto-connect lines allows the pipe routing to be expanded piece by piece via all accessible connections on the P&I diagrams.

Background:

With EPLAN Preplanning, users can carry out initial planning activities in EPLAN Platform as regards the technical aspects early in the engineering process. When engineering a machine/plant, there are individual phases in which the concept is continually refined and fleshed out from the initial rough ideas and designs until, finally, all the required documentation and information for assembly and manufacturing of the machine has been compiled. In the preplanning project phase, the concepts for the technical machine/plant scope are established and initial quantity structures estimated. The goal is to identify the most technically advantageous concept and to define the specifications for subsequent detail planning. Schematic creation and itemisation of the installation can all follow based on the preplanning. P&I diagrams are an integral part of plant documentation.

Benefits of EPLAN Preplanning version 2.7

- Defining piping with source and destination, even before a P&I diagram has been drawn

- Assigning identifying and descriptive data to piping such as designations

- Defining of the piping on the P&I diagram with the designed sequence of pipes and instrumentation

- Discretionary insertion or removal of piping instrumentation

- Piping-specific reporting