Engineering in the cloud

“Around 40 developers across multiple sites carry out cloud-based engineering work using EPLAN"

Enercon GmbH is Germany’s biggest manufacturer of wind turbines. The company uses cloud-based infrastructure on the EPLAN Platform to design its electrical engineering equipment – making it one of the first users of such infrastructure anywhere in the world. This infrastructure facilitates cross-site, multi-user engineering and even helps attract new skilled workers. When it comes to automating the assembly of its own enclosures, Enercon puts its trust in solutions from Rittal and Rittal Automation Systems.

On the market of the world’s leading manufacturers of wind turbines, Enercon is unique. The company focuses on onshore systems, and its gearless direct drive concept is unrivalled – a strategy that has brought it worldwide success.

Uniquely advanced

The new top model in the Enercon wind turbine range is the E-175 EP5, which boasts 6 MW of rated power and a maximum hub height of 163 metres. Its rotor diameter is 175 metres, making it one of the biggest available on the European market. Developed for (onshore) use in regions with moderate to light winds, this turbine is exceptional for its ability to generate low-cost electricity in these locations.

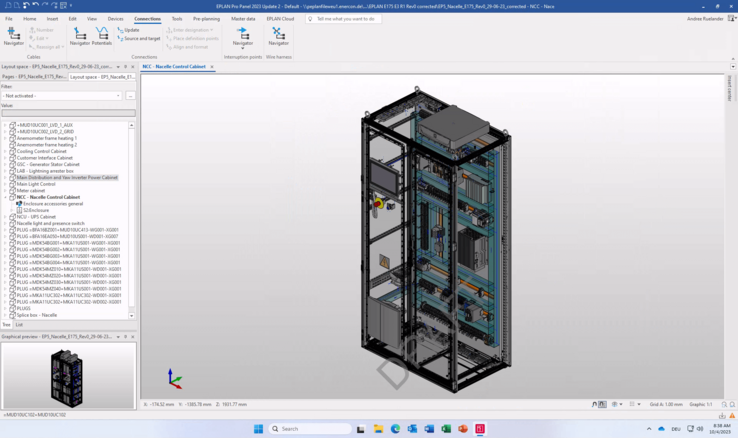

Another key feature is the integrated, latest-generation electrical engineering technology – the enclosures are located in the nacelle rather than at ground level. Electrical development at Enercon is also uniquely advanced within the industry. When planning the E-175 EP5, the design engineers used the EPLAN Platform, which is based in the Microsoft Azure cloud, for the first time. As Andree Rülander, Head of Electrical Design, explains: “We set up an EPLAN solution for multi-user engineering that makes simultaneous engineering possible for staff at our development sites in Germany, the Netherlands, Poland and India.”

For use worldwide – Engineering in the cloud

What was the key factor in the decision to shift the engineering platform to the cloud? “Our entire IT strategy is moving in the direction of the cloud, and this project was a pilot for this transition,” Rülander explains. “For one thing, it’s much easier to manage. You don’t need to worry about drivers, updates or administration – the cloud provider sees to all that. What’s more, it takes only 20 minutes rather than days to set up a new computer.” Even more importantly, however, multiple members of staff – including at different sites – always work on the same data model, which is always up to date. In consultation with EPLAN Consulting, Enercon decided against using a typical cloud solution. Instead, the on-premises processes and products are transferred to the cloud in such a way that they work exactly like a domain solution. With Microsoft Azure Marketplace as the starting point, the solution can be accessed via four different EPLAN Solutions apps, depending on the particular requirement.

Pioneering feat achieved

Configuring and installing this fundamentally new solution initially proved challenging. Detlef Harms, Project Manager at EPLAN, explains: “This was a premiere, and we certainly learned a lot from it.” The process therefore started with a proof of concept. The cloud-based electrical engineering solution only went live after that, in October 2022 – and is now working perfectly. What’s more, all parties involved in this task – EPLAN, Enercon and Microsoft – were breaking new ground. Harms explains: “Our goal was to create a scalable solution, and this is now accessible to EPLAN users worldwide, including in the Microsoft Azure Marketplace. In this case, we all worked together to achieve a truly pioneering feat.” Rülander adds: “Around 40 developers across multiple sites carry out cloud-based engineering work using EPLAN – and they are highly satisfied with the infrastructure, operation and responsiveness.” What’s more, Enercon has redesigned its engineering structure and now works on the basis of libraries. In concrete terms, this means the engineers can select which modules they need for a particular wind turbine from a predefined library.

Another reason why migrating the ECAD infrastructure to the cloud was no mean feat is that Enercon makes very extensive use of the EPLAN Platform. Besides EPLAN Pro Panel (enclosure construction) and EPLAN Electric P8 (electrical engineering design), the company also uses additional tools such as EPLAN Pro Panel Copper (for power distribution systems). It makes intensive use of the EPLAN Harness proD module for cabling and has also recently started using the Rittal Wire Terminal to process wires and cables. Siemens Teamcenter, which is used as the PDM system, was also migrated to the cloud recently.

Function-based structure

With the introduction of EPLAN, Enercon has, at the same time, also established a function-based structure for its electrical engineering. This involves division into modules, such as tower, adjustment system and electric distribution. Besides being logical, this structure makes work easier and also complies with the latest international designation standard for wind turbines, the “Reference Designation System for Power Systems” (RDS-PS). Conveniently, EPLAN supports this standard, which Enercon is now using.

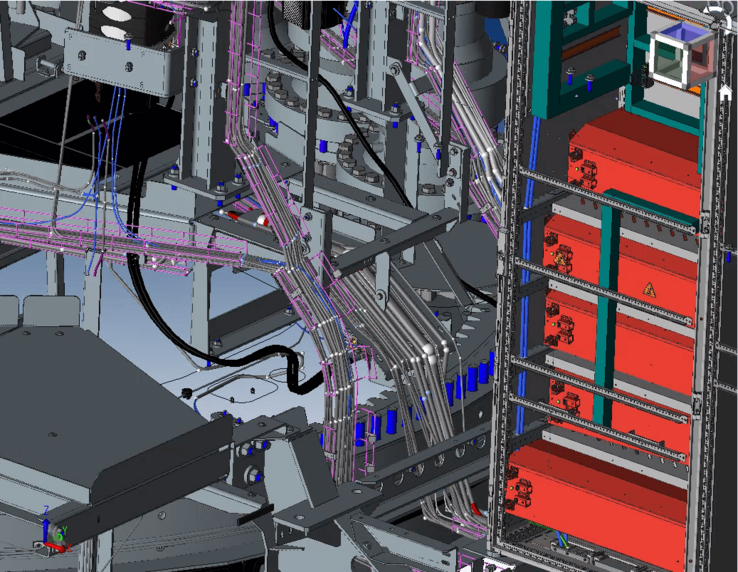

In all its projects and investments relating to design and manufacture, Enercon strives to achieve a largely automated end-to-end value chain. This also applies to the transfer of the “digital twin” that is created during the electrical design engineering process. This should also be the data basis in the real world, i.e. in production. Rülander explains: “In this respect, too, we have taken several steps forwards at once, because we have divided our manufacturing into process steps that correspond to the individual EPLAN modules. The digital twin serves as a data basis that we can use to derive manufacturing steps such as wiring, cable processing and enclosure assembly.”

Just how well this works in practice can be seen in the enclosure construction process. In the case of the enclosures for the new E-175 EP5 and E-160 EP5 series, the drill holes are defined in EPLAN Pro Panel and the data is transmitted to Rittal. Rittal then supplies Enercon with pre-drilled, pre-milled enclosure elements. The cable processing procedures are similar. In this case, Enercon works in collaboration with CadCabel – a specialist that is also an EPLAN partner.

A big step forward

After going cloud-based and following the practical experience of the initial months, the decision-makers’ conclusion is resoundingly positive. Rülander explains: “With the new cloud-based infrastructure for electrical engineering, we have taken a big step forwards and are now an industry-wide leader in this respect.” What’s more, a serious shortage affecting all companies is also being addressed: “The new infrastructure is also a plus point when it comes to attracting new skilled staff, because we are offering our employees a truly state-of-the-art, sophisticated design engineering environment.” What’s more, the managers are not only satisfied with the result of the cloud-based electrical design engineering – they are also very happy with the advice and training provided by EPLAN: “Quite simply, the collaboration has been, and continues to be, good – just like with external colleagues.”

Decision to opt for Rittal once more

During its development projects for the new E-160 EP5 and E-175 EP5 series – and in parallel with going cloud-based with EPLAN – Enercon also reconsidered the enclosure issue, carrying out a benchmarking process amongst key suppliers and testing sample enclosures. Rülander says: “The result was clear. The Rittal enclosures large and small continue to be our standard. One reason for this is the excellent mapping of Rittal solutions in EPLAN. In the future, this will become even more important for us, as we increasingly automate the assembly of our enclosures.

Better wiring with the Rittal Wire Terminal

Enercon uses various EPLAN tools for planning purposes and has also recently started using the Rittal Wire Terminal in its manufacturing department to process cables and wires. The fully automated wire processing machine from Rittal Automation Systems has become an important element of the production process and a genuine efficiency driver – because, when it comes to enclosure configuration, it is wiring that offers the greatest potential for improving efficiency and making savings. The Rittal Wire Terminal also makes it possible for companies to adapt and optimise their in-house processes quickly, and thus plays a key role in helping them maintain their competitiveness.