With clockwork precision

Maximum quality and the highest productivity are guaranteed at Grübl

The task: automate control cabinet construction. The solution: seamless integration, because EPLAN Pro Panel automatically delivers the data for the Perforex machining centre and the Secarex cutting centre from Rittal through the 3D digital twin of the cabinet. This guarantees maximum quality and the highest productivity at Grübl, an Austrian electrical engineering solutions manufacturer.

“Our founder started out in 1993 as the traditional one-man operation in his garage,” recounts Andreas Dunst, telling the story of the successful company. This was when Ekkehard Grübl began working on software development for automation projects. As is often the case for industrious entrepreneurs, success came quickly. Grübl’s solutions were in demand on the market and the hiring of his first employee in 1994 laid the foundation for the ongoing expansion of Grübl Automation Technology. Dunst was that first employee, as he proudly recounts, and is now the authorised signatory of a company that employs more than one hundred people and supplies customers all over the world.

Grübl Automation Technology is a full-service provider for electrical engineering systems: it designs and programs control systems; develops control technology systems in the areas of MES and DCS and many more; and has its own control cabinet construction facility, which was expanded and extended when the company constructed its new headquarters in Gersdorf an der Feistritz, Austria, in 2020. As Dunst explains, “We commission our systems in terms of both the electrical engineering and the control system technology.” Grübl customers can be found all across the industrial sector, but over the years there is one area that has emerged that the company is particularly good at: biomass. From municipal wood-chip heating in the cooperative housing sector to large combined heat and power plants for industry, the experts at Grübl develop and deliver complete systems for entire electrical system and control facilities – even when it comes to generating electricity from wood.

The majority of such projects are found in Europe, although Japan and Canada are other major markets – evidence of Grübl’s expertise in this market segment. This stems from the company’s flexibility, since the time from project planning to commissioning is often extremely short, as well as its expertise, which covers all technologies from high-performance low-voltage main distribution boards to complex sensor systems. “We have experts on board for each of these technologies, and their skills mesh with clockwork precision,” says Johann Weingartmann, director of electrical engineering at Grübl and the third employee to be hired (in 1995). What’s clear is that the company’s founder and CEO Ekkehard Grübl relies on expertise and continuity; constant employee turnover is not for him. He is thus highly committed to top-class training and further education for all of his employees, but especially employees in training.

The Path to the Future

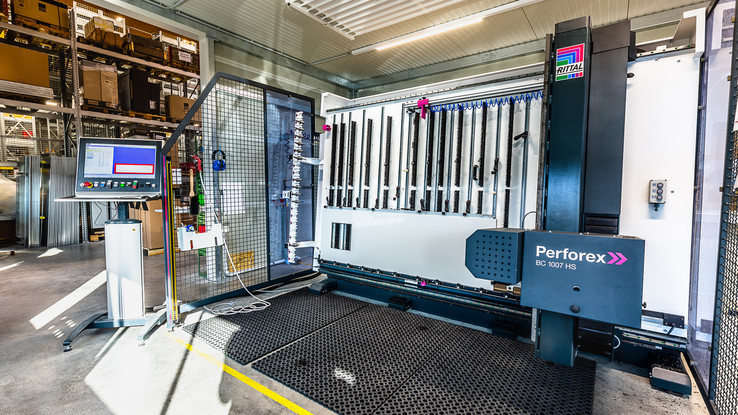

The first and third employees – Dunst and Weingartmann – were also the ones who came up with the idea of automating control cabinet construction at Grübl a few years ago. This was an obvious and promising choice, and has been rigorously implemented. To raise the quality of control cabinet manufacturing to the next level, the company invested in the Perforex BC 1007 HS milling and drilling centre, and the Secarex AC 18 cutting centre, both manufactured by Rittal, as part of the move to the new company site.

The Perforex milling centre is used for the mechanical processing of housings and flat pieces, including control cabinet doors. Just one example of this is the cut-out for a display unit, which the Perforex machine mills into the door. The Secarex cutting centre cuts cabling ducts, cable duct covers and mounting rails quickly, precisely and safely. The integrated label printer is used for project-specific labelling of the mounting rails and cable ducts. Both machines make a significant contribution to improved quality, a low, optimised waste rate and accelerated processes overall, not to mention the high degree of standardisation.

Core expertise: control cabinet construction has been part of the company’s business since the very start.

© www.martingold.at

The Added Value

“The Perforex and Secarex alone weren’t yet a complete solution for automated control cabinet production,” Weingartmann says. “We lacked a connection to engineering.” The path forward was almost predestined and led directly to EPLAN. Grübl was already pleased with its experience of using EPLAN’s solutions: “We’ve been using EPLAN Electric P8 since 2012, to our complete satisfaction.”

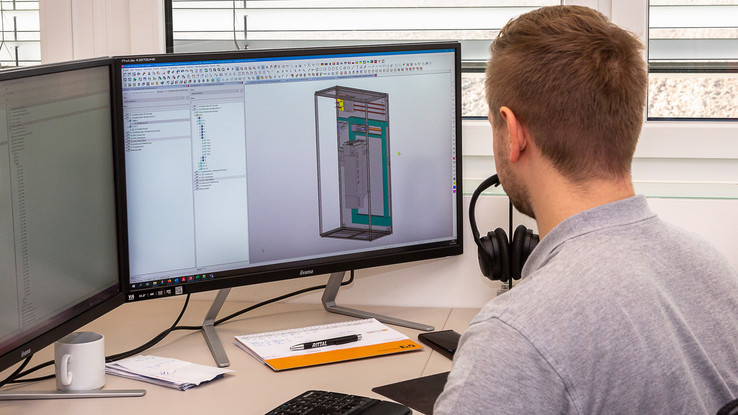

Grübl also implemented EPLAN Pro Panel as the 3D planning interface to production so as to optimise the control cabinet value chain. The entire engineering process for control cabinet construction has been running in three dimensions, on both the computer screen and the shop floor, for several months now. All these decisions quickly proved their value, especially as the advantages of the various EPLAN softwares speak for themselves. The showstopper is that the data automatically generated in EPLAN Pro Panel is transferred exactly as-is to both Rittal machines, which can take the data and begin using it without any further intermediate actions.

All the processing steps on the Perforex and Secarex machines are based on the data supplied by EPLAN Pro Panel: fast, easy and error-free. And since EPLAN and Rittal are affiliated companies and part of the Friedhelm Loh Group, there are absolutely no interface problems. Creating a digital twin thus significantly accelerates the manufacturing processes. Weingartmann: “EPLAN Pro Panel is an excellent engineering tool and we are also highly satisfied with the two Rittal machines. But it’s the combination of both worlds that gives us the really huge added value with respect to efficiency and productivity.”

Author: Engineer Martin Gold: journalist, author and photographer, Vienna