Full Speed Ahead

Systematically implemented digitalisation: Lenze SE is entering a new digitalised era with EPLAN and German Edge Cloud

There are numerous examples of the digital transformation that may seem ordinary on the surface but actually produce fairly spectacular results. Take Lenze SE, for example. The automation company for machine construction has set its sights on digitalisation with a thirty-person task force and external expertise from technology leaders including EPLAN and German Edge Cloud. To achieve its digitalisation goals, the company turned just about all of its in-house digital and analogue processes inside out – not just for show, but so thoroughly that even digital natives would be impressed.

Lenze Senior Vice President for Process and Quality Management Gerd Schüler

Starting in 2016, nothing at Lenze would ever be the same again, at least with an eye to the future: “Management gave us the mandate to make the front end of the business more competitive,” says Lenze Senior Vice President for Process and Quality Management Gerd Schüler. Optimising the front end specifically meant that potential customers should be able to effortlessly integrate Lenze products and digital services into their workflows. The special challenge here was that some “old” products, with their associated master data and documentation, weren’t suitable for digitalisation. Schüler: “It was immediately clear that we’d have to forge new paths that would call everything into question.” And, in fact, they did just that – not by exceeding existing technological limitations, but by completely blowing through them. Lenze went so far as to develop new products that could be digitalised and simply created new master data.

After five years of “new construction,” the interim results are impressive. Instead of server-based, on-premises solutions with limited storage and computing power, everything now runs in the cloud. Instead of static product data management with the continual creation of new data records and maintenance of countless variants, Lenze now relies on selected information units with stored rule sets. Instead of becoming increasingly dependent on proprietary platform solutions from individual software providers, Lenze now utilises various target systems as desired and necessary. Information is now intelligently coordinated and synthesised. Today, Lenze offers its customers a veritable extra added value in the form of complete EPLAN data sets that can be generated in seconds. And where company processes and information used to stop at the company’s internal firewall for security purposes, Lenze is now networking with the rest of the world.

“We rebuilt everything”

There are very big questions to be asked when a company wants to align everything with its customers, from product development to the digital twin in the product life cycle, while simultaneously becoming smarter as an organisation: “How do you synthesise information? How do you organise and structure it? How do you make the information so lean in its management that you can perform far better as a company with fewer people and become more agile?” As taskforce leader Schüler explains, the new start at Lenze wasn’t really a question of IT infrastructure: “There’s no lack of IT, you can buy all you want, but they’re just tools.” Suppliers and customers could only become faster if information was understood as a standardised structure and a high degree of re-use was implemented.

This is the case with the Easy Product Finder, the secret star of a whole series of “Easy Engineering Tools” that Lenze makes available to the market. The Easy Product Finder (EPF) is an online tool for searching, configuring, requesting quotes and ordering Lenze products. The EPF, in turn, is networked with a central information portal that has integrated EPLAN Engineering Configuration (EEC) as a cloud service. The configurator is administered by EPLAN affiliate German Edge Cloud – in the cloud, as the name suggests.

From Cloud to Cloud

Since summer, the EPF has been integrated into the EPLAN Data Portal, which for its part contains high-quality product catalogues from numerous component manufacturers. Anyone browsing the Data Portal who finds and clicks on a Lenze solution is automatically switched from cloud to cloud, that is, from EPLAN to the EPF environment on the Lenze website. Lenze Director of Team Processes and Data Bernd Spiegel explains: “The direct connection of our product configurator to the new EPLAN Platform means that customers quickly find the product they want. There’s no need to search for devices in extensive lists and customers find the product they need for their requirements. Incidentally, this integration also has significant advantages for Lenze as a manufacturer of products with numerous variants. Maintaining the contents of the configurator in EPLAN Electric P8 is much easier for us than maintaining all the distinct variants in a product series.”

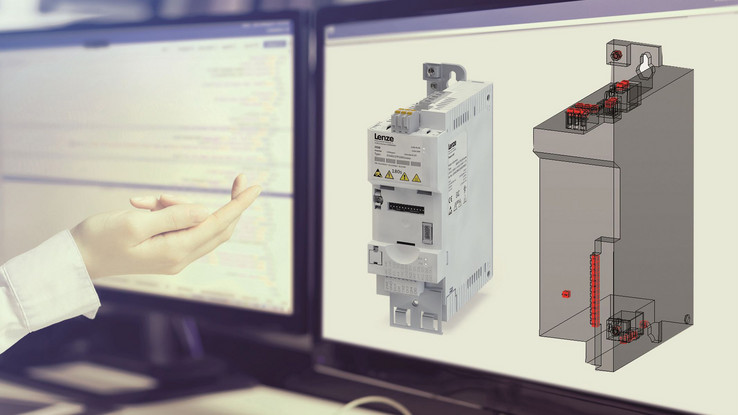

To take a real-world example, let’s say a user needs a frequency inverter. Using the Lenze Easy Product Finder, it takes just a few steps to find the suitable device from the i550 series of products. The defining characteristics such as the power rating, supply network type and type of fieldbus network are included in the selection. Once the user has chosen a device based on these parameters, the associated EPLAN data can be generated in the detail view of the device and then imported into the device management system of the client’s CAE solution. In addition to the configured product, the system also creates a complete set of EPLAN data, including the wiring lists, control cabinet layouts and manufacturing documentation from EPLAN Pro Panel. Lenze customers can download all the manufacturing data in an EPLAN format with just a mouse click.

“The machine does the rest”

Schüler explains the concept behind the EPF: “If you partition things in a sensible way, make them small and manage them differently, then you become quick. Then I have my ‘building blocks’ and can reassemble information quickly to serve a wide variety of target systems. If we combine this with rule sets and match it with variant configurations, information can be compiled in seconds when the customer decides what they want. The machine does the rest.” It does it faster by many orders of magnitude. Previously, the effort required to generate a data set took an average of two hours. Now it needs just seconds without any human intervention. To date, Lenze has invoiced 200,000 material numbers from a solution space of 1032 technically buildable data sets. “1032 means that there are more possibilities to individually design Lenze products than there are stars in the Milky Way,” Schüler says. “In principle, it approaches infinity. That’s why it made less sense for us as a variant manufacturer to store everything in the EPLAN Data Portal than it does for a volume manufacturer.”

Spiegel adds: “Previously, the data for EPLAN was always created manually. That may have been a good idea for low-variance inverters, controllers and accessories. However, we couldn’t adequately represent a product like the i550 with its many variants since the effort required for maintaining 2,000 to 3,000 variants would be too cumbersome and it would have become too confusing if we had listed all of them in the EPLAN Data Portal.” In the past, the companies made a compromise: Lenze only created data for the individual components of the i550, from which customers had to assemble the device themselves in EPLAN. Spiegel: “Problems regularly cropped up because customers only knew the designation for the complete inverter and couldn’t deduce the components from it.” The market definitely approves of the new ease of use of the Easy Product Finder with its features for generating and downloading the complete EPLAN data package (edz file) for each product variant – as evidenced by the steadily increasing numbers of clicks, which, according to Schüler, “correlate with rising sales.”

The physical product is one thing. Providing information appropriate to each variant is something else – which Schüler considers to be a basic requirement for customers. And he believes that if it’s a basic service, it should be provided. The EPLAN data sets must be available for engineering when or before the products are sold; it’s mandatory. “Not doing this means drowning in costs or slipping down to the level of a niche supplier. The fact is that data is used and combined to derive better decisions in terms of lower life-cycle costs. This requires the exact description of the asset. EPLAN is the best environment for this because the schematics depict every relationship amongst all the assets in a machine.”

Schüler continues: “We work with quite a few leading machine builders. They simulate the commissioning, operations, optimisation and maintenance of a machine at a point in time before it physically exists.” One of the things required for this is digital depictions for various engineering environments. What sets a company apart on the market are the accompanying services that accelerate workflows, including intelligent information and the ability to exchange it globally via standard interfaces. These are now almost even more important than the product itself, which is becoming increasingly interchangeable.

Moving from licensing to utilisation

Schüler says that with the Easy Product Finder they’ve now achieved the technological breakthrough. His colleague Spiegel adds, “We will have set up all the models, the complete portfolio with all the range of products, in the EPF by the end of 2022. In the end I’m just picking a lot of little pieces of information with their rule sets – it’s testable, it’s verifiable, it’s all much much easier. That’s why we’re so fast.” The effect within the company has been enormous. Once a customer has configured and ordered a product in the Easy Product Finder, bills of materials and workplans are automatically generated via an SAP interface. The operating principle is the same here, too: “Services are based on information keys that we move back and forth between different target systems. No matter what is in which cloud, it only seems that the complexity is increasing, but in reality it doesn’t.” This, by the way, is also in line with the attitude of user-centred Generation Z – the inevitable demographic of the next generation of Lenze employees.

Yet another thing Schüler appreciates about the implemented cloud solution is its simple functionality. The EPF is hosted with German Edge Cloud (GEC). “We have in fact found a very resilient architecture that is sustainable,” Schüler says. “We weren’t interested in licences, we wanted availability. This is absolutely the right strategy at the right time, and the whole thing is leanly integrated into our tool chain.” GEC, a member company of the Friedhelm Loh Group just like EPLAN, specialises in edge and cloud systems for companies with high requirements for protecting sensitive data. German Edge Cloud CEO Dr Sebastian Ritz explains: “We develop solutions that enable companies in different industries to actuate digital value creation – for instance with our ONCITE solution, which is ideally suited for performance-critical applications in Industry 4.0.” With the GEC hosting solution, Lenze was able not only to free itself from onerous hardware and software limitations but also to place the integrated implementation of the EPF in experienced hands. Schüler: “Of course it’s easier for us if we only have one contracting party, but it also worked out wonderfully because EPLAN has the domain knowledge for generating CAE data and knows how these things can be processed in the end.” Spiegel adds, “EPLAN has done many things very well and is clearly further ahead than the competition. Customising, training, response times – all top notch. And the fact that the people working with us at EPLAN have come to feel like co-workers is not simply par for the course. It’s remarkable.”

© Images: Lenze

Author: Ulrich Kläsener, Mediabridges

Profile of the Lenze Group

The Lenze Group is one of the leading drive and automation companies for machine construction. With almost 4,000 employees, Lenze generated sales of around 700 million euros in the 2020/21 financial year. Founded in 1947 as Stahlkontor Weser by Hans Lenze in Hameln, Germany, today the Lenze Group is present in around thirty countries with its own sales companies, R&D sites and production facilities, plus a network of service partners.

The group consists of 43 companies controlled by a holding company. The focus is on the marketing, production and development of drive automation technology (IoT gateways, controllers, inverters, drives, motors) and digital services for factory automation. The Lenze Group’s home market is traditionally Europe, where a good three quarters of the Group’s sales are generated. North America and Asia are important growth regions.