Mechanical and Electrical Engineering with Harness proD

Together with partner MA-IT, EPLAN seamlessly aligned electrical and mechanical engineering at MTA. How did Eplan tackle this? Paulus van Dreumel, Account Manager at EPLAN, Jules Simons, Lead E Engineer at MTA and Arne Vanvelthoven, E Engineer at MA-IT were closely involved in this project. In this article, they talk more about their approach and experiences.

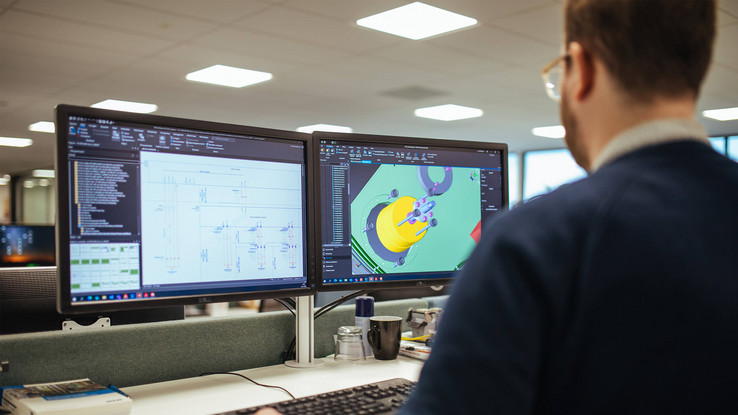

MTA's mechanical and electrical wire harness designs sometimes did not fit together, meaning that production designs had to go back to the drawing board. MTA streamlined this design process with 3D model development from Harness proD. The result was a 25% shorter lead time, half as many changes to the production of a wire harness and substantial savings in terms of repair costs and working hours.

Back to the drawing board

Cabling still sometimes falls between the cracks when developing machines. Mechanical engineers have their own visual model without wiring, while electrical engineers work with electrical diagrams. "As a result, design flaws related to cabling only came to light in the production phase. Consider a lack of space that meant cables and plugs did not fit in practice or missing drill holes for fixing," says Simons. Then the design had to be modified on the spot or we had to go back to the drawing board – with all the associated delays and repair costs.

Win-win-win

How can we better link mechanical and electrical design models? "We provided MTA with Harness proD – software for developing three-dimensional wire harnesses. To integrate this software with existing EPLAN programs, customise it and optimise it, we engaged certified partner MA-IT. We familiarised MTA with Harness proD through training and set-up," states Van Dreumel. Vanvelthoven adds: "At MA-IT, we seconded an engineer who supports MTA on the shop floor for everything to do with working with Harness proD." A win-win-win situation according to Vanvelthoven: "At MA-IT, our operational expertise with the EPLAN software ensures that MTA gets everything out of the engineering process and EPLAN platform. In addition to MTA, EPLAN is also reaping the benefits of that."

"Working proactively instead of reactively"

Proactive

Harness proD makes the engineering process at MTA much more efficient. "With the 3D models, we can work proactively instead of reactively," says Simons. "Many design flaws come to light before the production phase. As a result, we do not need to adjust production designs as frequently. As an example, instead of thirty, we have an average of fifteen changes per machine. This results in considerable cost savings, as one change costs around three hundred euros. This is both due to delays as a result of idle production and testing processes, and the extra working hours and repair costs." In fact, with Harness proD, MTA spends 25% less time on the design and production of the cabling. That means labour costs are also reduced by the same factor.

3D insight

In case of issues or questions, all MTA employees involved can directly consult the 3D model of a produced machine. This applies to mechanical and electronic technicians, in the office and on the shop floor. Simons: "If you open a model, you can see how the cabling runs in the mechanical design in three dimensions. You can zoom in, rotate the view or look at the underlying electrics. If you click on a cable, you will see the details, such as length, diameter, where connectors are located and what the application is. That means you never have to make cables longer just to be sure and you don't have to make any additional changes to them."

"Up to 25% less time spent on cabling"

Enjoyable working

By linking to EPLAN programs, documentation is automatically maintained. Simons gives an example: "Has a cable been shortened or converter replaced in the 3D model? Then these changes are automatically reflected in the documentation, such as the parts and order lists. This means less manual administration for MTA employees and Harness proD makes work more enjoyable in a variety of ways. This way, technicians spend less time fixing errors and have more time to think about innovations and other improvements to the design and production process."

Attractive employer and greater agility

The technical improvements to the design and production process result in a variety of business benefits, including satisfied, more productive employees first and foremost. In this way, Harness proD makes MTA a more attractive employer – a not insignificant factor in times of shortages of technical staff. In addition, the shorter lead time of machines and devices allows MTA to meet the market demand faster. This results in satisfied customers and makes the company more agile.

About MTA

MTA develops and produces high-tech mechatronic systems. It does so from its production facility in Helmond for customers including original equipment manufacturers (OEMs) and scale-up and start-up companies in various markets. Efficiency and quality are paramount at MTA. That is why the company works uniquely with customers, partners and suppliers according to its own V2 method. By involving everyone in product design from the start, MTA can design and build machines in such a way that they can then be series-produced in a quick, economical and high-quality process.

MA-IT is a brand-independent supplier of industrial automation solutions and an EPLAN-certified partner for customised library filling and further standard and process optimisation. With 130 engineers, programmers and consultants, MA-IT supports organisations from various industries to successfully implement projects. The focus here is on transparency and added value for people, the environment and society. MA-IT is a recognised training company that is continuously committed to further developing employees' talents and skills.

What is Harness proD?

Harness proD is EPLAN software for developing three-dimensional wire harnesses. Harness proD makes it possible to combine mechanical and electrical models, meaning mechanical and electrical engineers work with the same 3D model using the same digital cabling workflows. This results in a more efficient engineering process and optimal documentation of pre-configured cable assemblies, among other things.