Proportional Automation

Electrical engineering designs and control cabinet construction at Elektroanlagen Röring

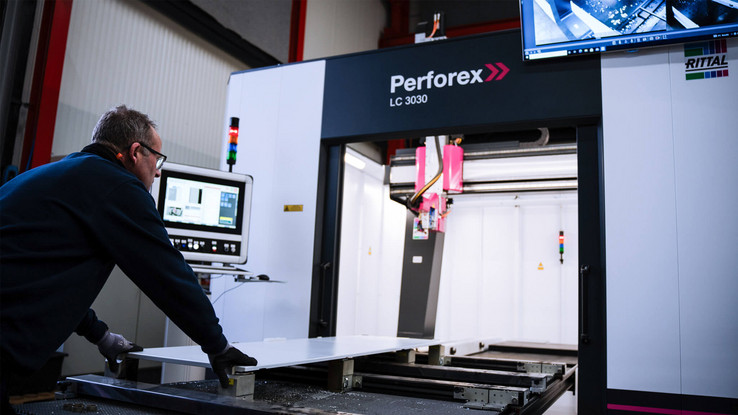

Control cabinet manufacturing is highly automated at Röring. The mechanical processing is handled by a newest generation Perforex LC laser centre, while EPLAN Smart Mounting supports the company’s wiring technicians. EPLAN Pro Panel is used for routing, and everyone involved in the planning and design of the control cabinets is working with a digital twin that is stored in the cloud. Röring uses this clear concept to plan, design and build complex control cabinets and switchgear systems for numerous clients, including biogas plants and highly automated production lines.

Everything is connected here: control cabinets for an industrial production plant in Röring’s testing area.

What do an event arena for musicals, a biogas plant and a robot-supported production line for automotive components have in common? For all three of them, Elektroanlagen Röring, based in Vreden, Germany, plans and builds the control cabinets and, if needed, can also take over the complete electrical engineering as well as the automation technology and PLC programming. As different as these three application areas may be, they are all demanding projects that require a large number of control systems and, naturally, the automation technology, control cabinets and automation technology are all correspondingly complex.

Core expertise: Control technology for biogas plants

A typical project for Röring can be viewed “live” in the control cabinet manufacturing facility – which make sense, as it underscores the company’s main industrial focus at the moment. CEO Markus Aagten explains: “Beyond Germany, and even beyond Europe, we’re known as the experts for control cabinet construction for biogas plants. We have a very good market position, also for special plant systems such as gas-to-grid operations.”

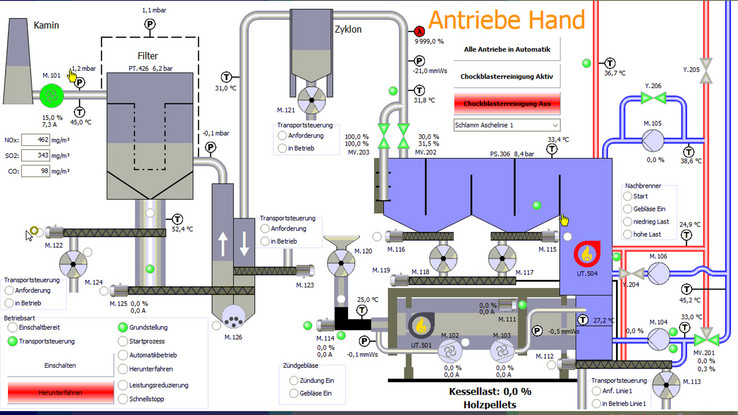

One of Röring’s flagship projects in this field is Europe’s largest biomethane plant, in Friesoythe, Germany. Even the switchgear system currently being tested for it is complex. Markus Aagten: “Biogas production is not a discrete process with many consecutive steps, but rather one large overall process with many variables that influence each other.” That is why, as can be seen from the numerous connecting lines, literally everything is connected to everything else in the up to sixty-three control cabinet system panels. The testing and final approval are therefore extremely challenging.

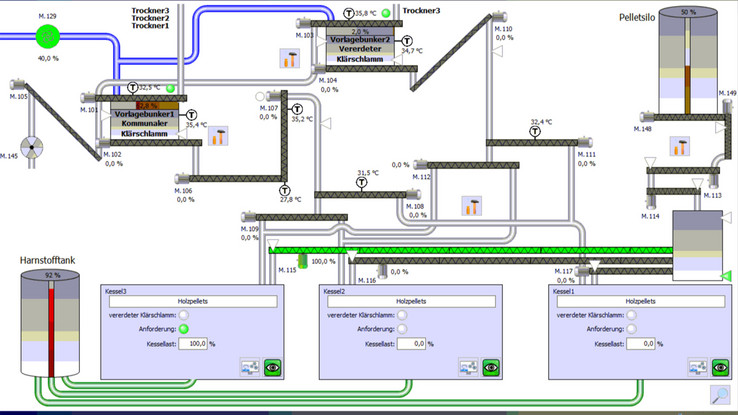

Röring has developed its own tool for the collection, recording and visualisation of process data: DiaLogo®, which is popular in the process industry.

Electrical engineering: “Get more done with less”

In electrical engineering, Röring is in its tenth year of working with the EPLAN Platform. Markus Aagten: “Our goal is to achieve a major impact using smart solutions, and we are succeeding in this.” The electrical engineering designers use EPLAN Electric P8 to create multi-line as well as single-line schematics – usually based on STEP data provided by the customer. The also make extensive use of the EPLAN Data Portal, as well as standards and macros that they have developed in-house. EPLAN Pro Panel is used for designing control cabinets in 3D as well as for the routing, bundling and assembly of wires and cables. And once the engineering has been completed, the EPLAN data continues to be used extensively. Electrical engineer Kevin Korte explains: “We upload the completed schematics via eView to the EPLAN Cloud. Our colleagues in the workshop use this as their basis, and thanks to the greenlining and redlining, everyone involved always has access to the most up-to-date data.”

Workshop: Automation from the very start

Control cabinet manufacturing at Röring is automated from the very first step, right from the start. When the company introduced EPLAN in 2014/15, they also purchased a Perforex system for the mechanical processing. It is still being used today, but laser processing is now also available with the Perforex LC. Markus Aagten: “This is a definite step forward, starting with the feeding of the system on trolleys, with no need for clamping. The laser finds the zero point itself and can process the cabinet on almost all sides – without deburring and in very high quality.” If needed, Röring can also handle the mechanical processing of the switch boxes. In addition, a lorry from Rittal delivers control cabinets and their components almost every day. The cutting of DIN rails is also automated – with a Secarex cutting centre from Rittal Automation Systems.

Smart assembly and wiring

Automation in assembly is a more recent development – the company has been using EPLAN Smart Mounting for around one-and-a-half years. This means that technicians can see the next assembly steps on a laptop screen (with touch functionality). As soon as they confirm that a step has been completed, the next step is displayed. This accelerates the process and simultaneously standardises it – but these are just a few of the multiple advantages. Markus Aagten: “Production has all the data that we generate in the planning phase readily available. And the colleagues in order planning, for instance, can always see the current state of assembly. This has proven itself in practice.” Röring recognised these advantages early on and was therefore one of the first users of EPLAN Smart Mounting.

Röring made the conscious decision to not use automated wiring, as their wires and cables are assembled by a vendor. However, when it comes to wiring, while they don’t use automation, they do use something that simplifies the work: “We’ve been wiring for the past two years with EPLAN eView. The technicians see the schematics on the screen and can thus plan the next wiring step.”

Röring electrical engineers use EPLAN Pro Panel to design control cabinets in 3D.

The digital twin at work: EPLAN Smart Mounting shows the next step for assembling a control cabinet.

Value creation is shifting to the planning phase

As Markus Aagten sees it, the gradual increased use of the EPLAN Platform has made the company’s manufacturing leaner: “Value creation is shifting into the office and into the planning phase – partly because the quality of the plans is crucial for efficient manufacturing. This is a path we will continue to follow.” They’re preparing one of the next steps right now – the order-picking trolleys will be equipped with a scanner in the future. This will allow manufacturing employees to scan any component and see its location in the control cabinet on the computer screen, thereby saving even more time during assembly.

Conclusion: Cleverly automated

Looking back, Röring has intensively digitised (including using EPLAN Pro Panel, EPLAN eView and EPLAN Smart Mounting) and automated (such as with laser processing using the Rittal Perforex LC) key steps in its control cabinet planning and manufacturing processes. For other work steps, especially for wiring, the companies relies more on worker support than automation. Markus Aagten: “We very carefully examine what and where we automate and always keep an eye out for ways to make work easier through ergonomics and visualisation.” This is clearly a good recipe for success, judging by Röring’s development over the past years.

Division of Labor: Two Companies, One Mission

Founded by Stefan Röring in a garage in the year 1990, the company started out building control cabinets and was quick to embrace digital processes – think 3.5-inch floppy discs. It also clearly recognised the importance of nurturing young talent: Markus Aagten was hired as the first trainee in 1992. Today, he’s the CEO.

In addition to industrial companies in the energy and environmental technology sectors, Elektroanlagen Röring’s customers primarily include mechanical engineering companies, municipalities, agricultural businesses, the food industry, and planning and architecture firms. Programming is also part of the company’s range of services and a significant portion of the workforce specialises in this field.

Shaping the Future: Röring Grows and Evolve

The company’s affiliate, Energieanlagen Röring – which is planning to relocate in summer 2025 to expand its warehouse, production and office facilities – focuses on manufacturing and selling transformers and load-carrying switchgear systems. The charging infrastructure for e-mobility is also part of the company’s development and manufacturing portfolio.

The two companies together employ around sixty people and have been undergoing a generational change for some time now. Right now, the first generation is handing the baton to the second: Marlies and Stefan Röring are taking a step back and handing over responsibility to Anna Röring and Markus Aagten – with fresh ideas and the shared goal of continuing to write the company’s story of success.

Everything at a Glance: A Proprietary Visualisation System

One of the special features of Röring’s switchgear systems and control cabinets is the DiaLogo® control software that the company develops in house. It has a modular structure and monitors, controls, measures and regulates all machine and plant process data on site or via remote maintenance.

Process data such as temperatures, pressures, rotational speeds and fill levels are displayed on freely configurable curve diagrams or in clear tables. Deviations from target values are detected, recorded and reported. This makes it possible to rapidly predict, analyse and correct errors.