ECAD: Training in the Virtual Classroom Proves Its Worth

Online instead of “live”: EPLAN training courses at EDAG Production Solutions

EDAG Production Solutions is purposefully expanding its spectrum of services into demanding industrial production sectors. The full-service provider for production engineering is using EPLAN training courses to help strengthen its automation technology business and train its mechanical engineers. Because of the pandemic, the planned in-person training at the EPLAN Training Academy has been replaced by online courses. All those involved are keen for more.

The transformation currently underway in the automobile industry is naturally influencing the entire value chain for automotive engineering – including engineering service providers that plan and develop turnkey production plants for automobile manufacturers and suppliers.

Project: Skills for Project Engineers

One such company is EDAG Production Solutions (EDAG PS), headquartered in Fulda, Germany, and with more than 1,300 employees worldwide. This subsidiary of the EDAG Group was originally focused on the automobile industry. Since companies in other branches were also demanding highly automated production solutions at the highest quality standards for their value chains, EDAG PS decided early on to offer its services to other sectors, including medical technology, food and beverage, logistics distribution, optics and optoelectronics, and machine building generally. The company has been systematically expanding into these target industries, which also means that they need more electrical engineering designers and fewer specialists for mechanical engineering (e.g. for planning car body construction plants).

The consequences are obvious. EDAG PS Senior Expert Oliver Dierolf explains: “We are training mechanical design engineers from multiple locations to become electrical design engineers. The demand for our services in this field is growing strongly. This allows us to offer our employees interesting perspectives while we simultaneously create an important prerequisite for broadening our international customer base.”

Designing production solutions customised to its customers’ needs is the core business for EDAG PS – as seen here in the virtual representation of an assembly system for Ruhr University Bochum.

Image: EDAG Production Solutions GmbH & Co. KG

The electrical designers at EDAG PS plan complex production plant systems for demanding customers from a variety of industries.

Image: EDAG Production Solutions GmbH & Co. KG

Basic Idea: Courses at the EPLAN Training Academy

As the first step, EDAG PS developed a multi-stage training programme that imparts comprehensive e-technology knowledge: from the foundations of electrotechnology, to hardware planning and PLC programming, to robotics. Dierolf: “It was important for us to take a diverse approach and not just train the youngest among us.” That’s why participants of different ages and from five company locations were to take part in the programme, which was designed to last five months. It almost goes without saying that EPLAN Electric P8 is part of the training programme. After all, both EDAG PS and many of its clients work with EPLAN Platform.

Originally, the plan was for the employees to take the courses at the EPLAN Training Academy, which has numerous locations across Germany and internationally. EPLAN offers a comprehensive training programme here: from basic to advanced training, to courses in methodology and automation. The training programme can be completed with an exam to become an EPLAN Certified Engineer.

Online Instead of “Live”: Can It Work?

That was the idea. Then came corona, just before the in-person courses were supposed to start. EDAG PS was faced with the question: Can this demanding training concept be realised via online courses without any loss of quality? EPLAN Training Academy Director Harald Weiß was able to persuade the people responsible at EDAG PS and at the same time offer the EPLAN Training Quality Guarantee as the “fallback” position: “If a customer isn’t satisfied, the online training can be repeated in person – free of charge.”

Teamwork was key in the preparation for the courses: EDAG PS provided computers and monitors for 22 participants, while the EPLAN Training Academy provided the training environment, including all the necessary software licences and digital training materials.

ECAD Training in the Virtual Classroom

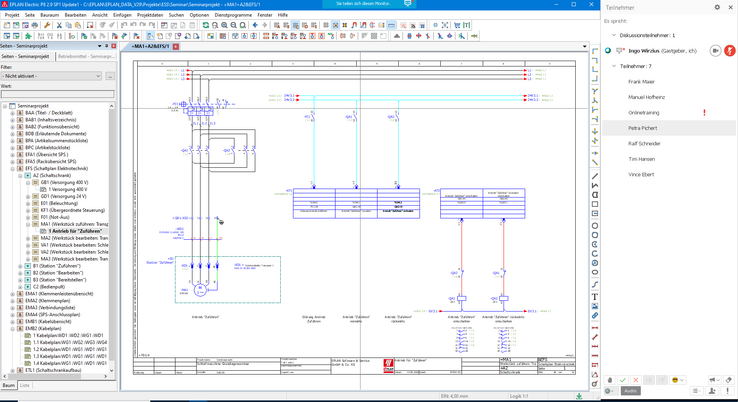

The EPLAN Academy concept for online training courses is based on a combination of Citrix and Webex as the work platform. Weiß: “Citrix depicts the complete training environment, while the classroom is realised with Webex, which enables communication among all training participants. We reproduce the entire contents of an in-person training 1:1 in the online training.” As part of the training concept, each participant is given a specific design task, which is divided into a knowledge transfer phase and a practical implementation phase. In the virtual classroom, participants can ask the trainer questions or communicate with others via a chat function. The timing of working phases and breaks was also adapted to the online requirements.

The Changeover: Easily Managed, Even Better With Training

What do the people who took the course think about the concept? Marie-Theres Schäfer, who participated in the first training programme from the company’s location in Eisenach, Germany, describes her experience: “From my point of view, it worked smoothly. Since everyone was working on their example project, the work is practice oriented. Communication also worked well; I quickly received help when I had questions.”

So getting started with and switching to EPLAN is easy even online, as Schäfer confirms: “I had a very positive first impression. Changing from other engineering programs is pleasantly easy to manage. EPLAN Electric P8 may initially seem a bit confusing at first due to its many functions and symbol buttons. But the more you work with the program, the more you learn to appreciate them, particularly the buttons. I especially liked the fact that the new versions of EPLAN include tutorials, with videos that explain frequently asked questions in a user-friendly way.”

And although getting started wasn’t that difficult, Schäfer highly recommends starting with a basic EPLAN training course: “It is definitely very valuable. For example, the trainers show you some tricks that make working with the software much easier.”

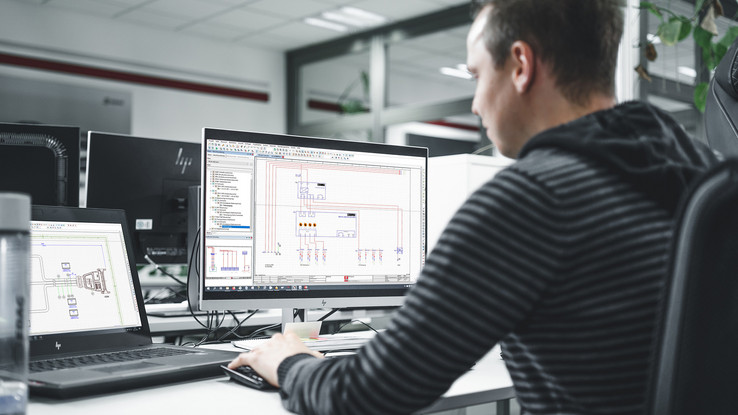

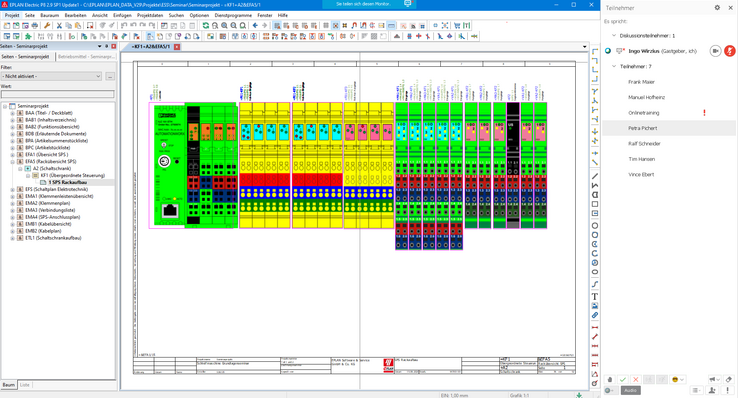

Participants in the EPLAN training courses work on specific projects.

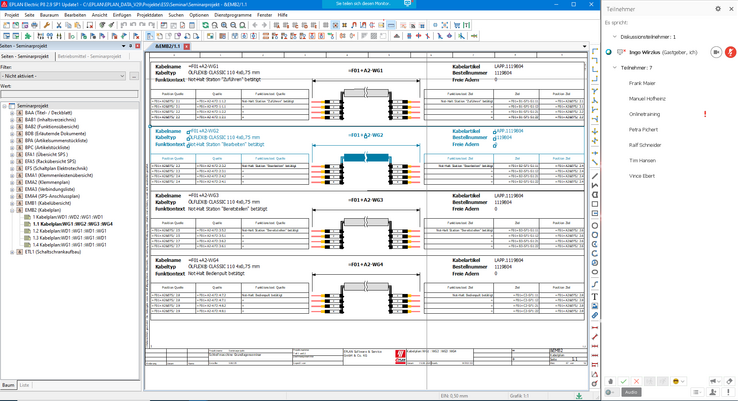

This is how it’s done: in the training courses, participants also become familiarised with designing control cabinets, which belong to the EDAG PS services portfolio.

The EPLAN trainings cover the entire EPLAN software portfolio.

The Future of Training: A Mix of Online and In-Person Events

Today, the higher-ups at EDAG PS are convinced by the online training concept – even though it originally started as an emergency measure. Dierolf: “We received positive feedback about the course’s contents from the participants. And from the company’s point of view, the online training courses have big advantages. Participants don’t have to travel and thus aren’t taking any risks during the pandemic, and we save on costs as well.” In the meantime, twenty EDAG PS employees have completed EPLAN online training courses, and more will follow in the near future.

EDAG PS isn’t the only company with a very high level of acceptance for online training. The positive feedback from course participants and the customers’ desire for both in-person and online options, point the way forward: the EPLAN Training Academy now offers its entire portfolio of courses online as well – even worldwide.

Author: Gerald Scheffels, freelance specialist journalist, Wuppertal, Germany