Leading the way in innovative joining solutions

Making the case for design automation

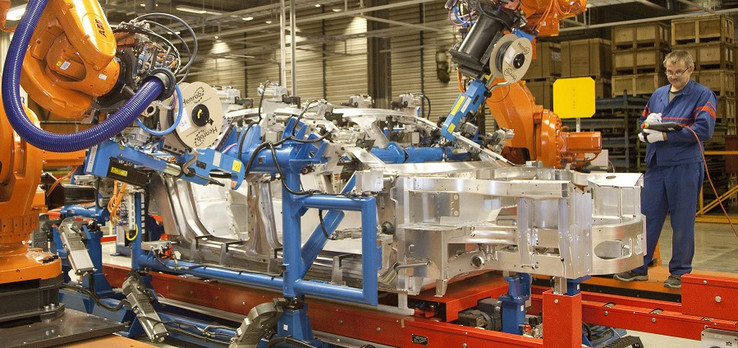

Henrob’s reputation as the pioneer of modern day self-pierce riveting has been built on providing creative products and joining solutions for its customers throughout the world. Its philosophy is to design reliable, robust solutions for production. This is achieved with the help of 3D computer aided engineering (CAE) software, which allows in-depth modelling of tools and product access studies.Self-piercing riveting is a relatively new and increasingly used form of mechanical joining, suitable primarily for sheet material joints. The technology is particularly applicable for the joining of aluminium, dissimilar materials and coated materials.

Henrob supplies many major players in the automotive industry such as Jaguar, Land Rover and Aston Martin. High performance vehicles particularly benefit from the technology offered at Henrob as a result of being manufactured from lightweight materials. Some research has also been done into the fact that the self-pierce rivets are safer in an accident. The company provides a complete service, including the design, manufacture, supply and commissioning of self-pierce riveting equipment as well as the manufacture and supply of self-pierce rivets and studs. All Henrob’s tools, cabinets, accessories, magazine tools and stands are designed with EPLAN software.

The company currently uses EPLAN Electric P8, the solution for unlimited possibilities in interdisciplinary electrical engineering; EPLAN Fluid, which supports fluid engineering with automated documentation; and the EPLAN Data Portal.

Switched on

Henrob’s Advanced Engineering team leader Antony Evans has been the driving force advocating EPLAN. When he joined the company in 2001, the company was using AutoCAD, which was very time consuming. With a growing need to use electrical schematics in their projects – particularly for customers such as Jaguar – he persuaded the company to switch to EPLAN 5.4 in 2003. The impact on productivity was immense; efficiency increased by 100% as design time was reduced from 4 weeks to 2 weeks.The migration to EPLAN Electric P8 followed in 2011. Again, Henrob saw an increase in productivity of 10%. The switch – first to EPLAN 5.4, then to P8 – has also reduced the engineering cost attributable to a typical project and has led to improved and more consistent documentation.

Benefits and possibilities

Since implementing EPLAN, Henrob has benefited from a number of operational improvements, including faster and more reliable generation of documentation, the reduction or elimination of errors and greater documentation for field service.The engineering team, in particular, has found a number of EPLAN features extremely useful. These include automatic BOM creation, terminal interconnecting diagrams, and plugs and sockets referencing. Of course, they have also been using EPLAN for drawing.

Faster and more accurate

Applications Engineer Phil Ackerley highlights some of the benefits: “EPLAN has encouraged best practices in our company and improvements have been made in a number of areas. We are able to offer faster, more accurate project quotes as well as generate more reliable documentation. We are also benefiting from faster integration of data corrections and customer-specific changes.” Another key benefit for Henrob is the fact that EPLAN converts to PDF documents, which allows links to other documents within the schematic, ensuring that all vital information is available at the click of a button.

Service and support

Aftersales service was also critical for Henrob, not just for the quality of initial training and follow-up help desk support, but for recognising how to make better use of EPLAN’s rich menu of standard features and optional add-ons. “The service from EPLAN has been very good. The support, in particular, has been fantastic. EPLAN has not only supported us by providing software tools, but also by assisting with the implementation and by offering advice,” says Evans.

The EPLAN Data Portal: drawings made easy

The EPLAN Data Portal, provides online device data of over 390,000 components that are controlled and managed by over 60 manufacturers such as Festo, ABB, B&R and Phoenix contact. As a result, the data portal has delivered another productivity improvement opportunity due to the wealth of information that is immediately available. Order numbers for procurement, technical macros for creating schematics, function templates for intelligent device selection and preview screens can all be transferred simply and effectively by dragging and dropping from the EPLAN Data Portal into the project. This effectively does away with the time consuming creation of master data.

What the customers needed: EPLAN

Improvements have not only been noted internally, Henrob's customers have directly commented on the increase in quality of documentation. Customers have also benefited from Henrob's ability to draw easily draw different product configurations, to show how customers new configurations could improve their end product.

Ultimately, Henrob has increased productivity, profitability, business efficiency and customer satisfaction made possible by extracting the maximum benefits from EPLAN’s industry-leading design platform. Moreover, EPLAN has reduced the ambiguity of information and almost completely eliminated design error, enabling Henrob to place full trust in the CAE tool.

"We have been so impressed with the improvements in productivity that we are considering expanding the number of licenses we have at Henrob"